Palm oil fractionation is an important process used to separate palm oil into liquid palm olein and solid palm stearin, both widely used in food, cosmetics, and industrial products. As a professional manufacturer of palm oil processing equipment, Henan Glory provides complete palm oil fractionation plants with daily processing capacities ranging from 1 to 1200 tons, offering customized solutions for both small workshops and large-scale industrial facilities. Below, we introduce the key equipment that makes up a palm oil fractionation plant and highlight their unique features and functions.

The crystallization tank is a core component in the palm oil fractionation plant, designed as a cylindrical vessel with a large cooling surface area to facilitate efficient and uniform heat exchange. It is equipped with water cooling coils and an advanced stirring system. The water cooling coils provide a large heat exchange area to ensure uniform and controlled temperature reduction, while the specially designed stirrer maintains consistent movement of the oil throughout the palm oil crystallization process. This prevents sedimentation and promotes the formation of stable, well-defined crystals, which is crucial for effective separation in subsequent stages. In addition, this crystallization tank is fully insulated to maintain precise temperature control, which is essential for achieving high-quality palm olein and palm stearin separation. Suitable for both small and large palm oil fractionation plants, our crystallization tanks are built for durability and optimal performance.

The crystallization tank

The crystallization tank

The cooling unit is an integrated system that supplies the cooling energy required during the crystallization stage. It is engineered to gradually lower the temperature of the palm oil, allowing palm stearin crystals to form properly without premature solidification of the olein fraction. Its core equipment, the chiller tank, circulates a cooling medium to the crystallization tanks. Additionally, the unit includes an air storage tank, freezing dryer, and air compressor, which work together to provide clean, dry compressed air. This air powers the pneumatic components of the membrane filter and other automated units. Designed with energy efficiency and operational safety in mind, the cooling unit can be customized to match different capacity requirements and ambient conditions.

The cooling unit

The cooling unit

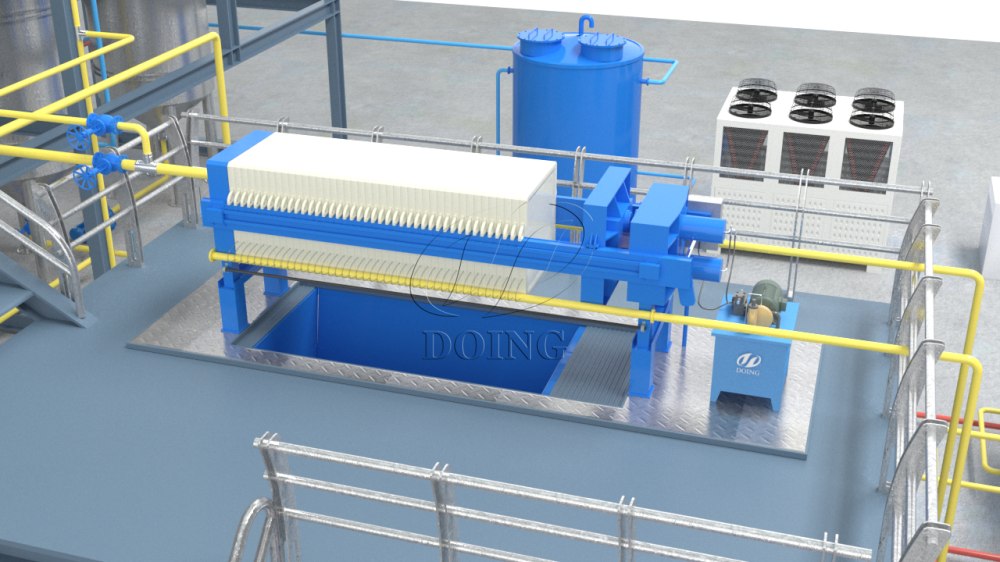

After crystallization, the oil slurry is transferred to a membrane filter for solid-liquid separation. The filter uses a series of filter plates and membranes to separate the liquid palm olein from the solid palm stearin under pressure. This equipment is known for its high filtration efficiency, low residual oil content in the filter cake, and fully automated operation, which minimizes manual intervention. Its simple yet effective design ensures reliable performance and easy maintenance, making it suitable for continuous industrial operation. Built with robust materials, it ensures long-term reliability and is capable of handling different volumes, making it suitable for small, medium, and large-scale palm oil fractionation plants.

The membrane filter

The membrane filter

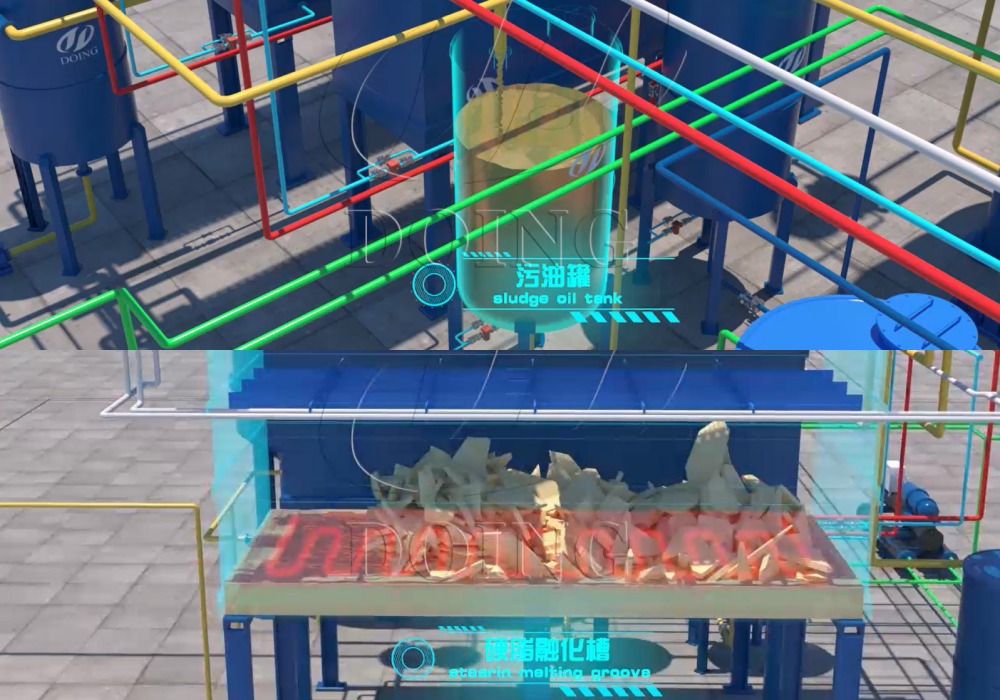

In addition to the main components, the palm oil fractionation plant includes several important auxiliary pieces of equipment. For example, the sludge oil tank collects and temporarily stores oil from various processes for recovery or treatment, minimizing waste and improving overall efficiency. The stearin melting tank is specifically designed to melt the filtered palm stearin cake into liquid form for easier handling, storage, or further processing. The auxiliary equipment works together with the key equipment to form a complete, continuous, and automated production system.

The sludge oil tank and stearin melting tank

The sludge oil tank and stearin melting tank

Henan Glory is committed to providing high-quality palm oil fractionation plants that meet global standards. With our expertise and flexible manufacturing capabilities, we can offer complete solutions to meet your specific needs. Contact us today to learn how we can help you build a highly efficient and profitable palm oil fractionation plant!

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!