The success of a palm oil mill plant hinges on three critical goals: minimizing losses, stabilizing quality, and controlling costs. Achieving these requires a deep understanding of the core palm oil processing steps. At Henan Glory, we specialize in optimizing this entire palm oil production process with reliable equipment, helping you extract more higher-quality oil from every bunch.

Palm oil processing steps

Palm oil processing steps

Overview of the Palm Oil Production Process:

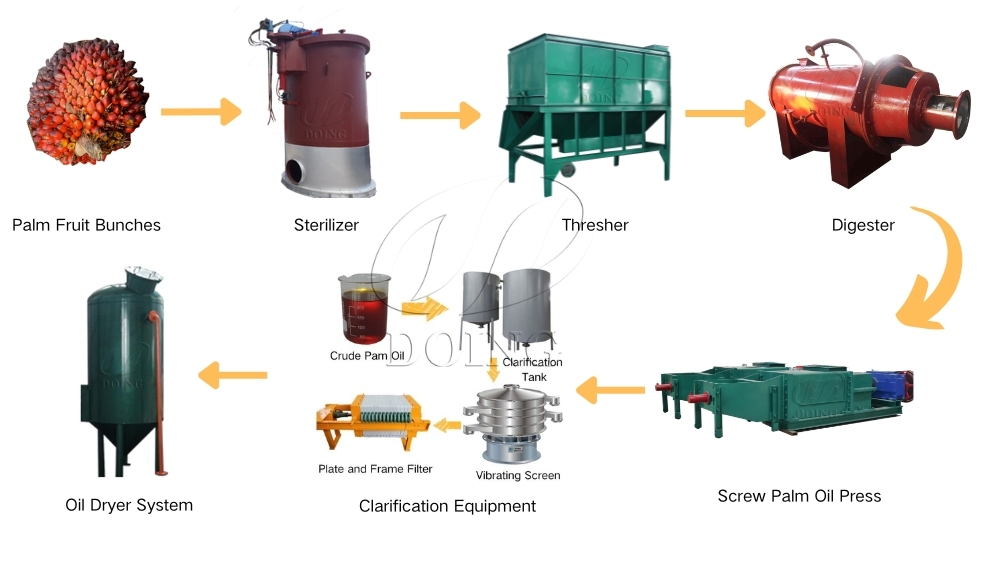

The journey from fresh fruit bunches (FFB) to crude palm oil (CPO) follows a streamlined path: FFB → Sterilization → Threshing → Digestion → Pressing → Clarification → CPO Storage.

1. FFB Reception and Weighing

Purpose: To ensure timely processing and prevent oil quality deterioration.

Process: Fresh fruit bunches are delivered to the mill plant and weighed. A key requirement for quality control is that processing must begin within 48 hours of harvest to prevent a spike in Free Fatty Acids (FFA).

2. Sterilization

Purpose: Inactivate fruit enzymes, soften the fruits, and prepare for subsequent palm oil processing steps.

Process: Load FFB into a sterilization tank for high-pressure steam cooking (60-90 minutes).

Functions: Prevents FFA formation, facilitates fruit separation, and reduces microbial content.

3. Threshing

Palm fruit thresher

Palm fruit thresher

Purpose: To separate the individual palm fruits from the empty fruit bunches.

Process: The sterilized bunches are fed into a rotary drum thresher, where the mechanical action detaches the fruits. The separated fruits then move forward in the extraction process, while the empty bunches are typically used as boiler fuel.

4. Digestion

Purpose: To break down the fruit's cellular structure and liberate the oil.

Process: The fruits are heated and stirred in a digester vessel to form a uniform mash. This digestion stage is vital for maximizing the oil yield during the next extraction step.

5. Pressing

Double screw palm oil press machine

Double screw palm oil press machine

Purpose: This is the core of the CPO production process, where oil is physically separated from palm pulp.

Process: The mash is fed into a double screw palm oil press, which applies intense pressure to squeeze out the crude oil. The output is a mixture of oil, water, and solids, while the pressed cake is further processed for kernels.

6. Clarification and Purification

Crude palm oil clarification equipment

Crude palm oil clarification equipment

Purpose: To purify the crude oil by removing impurities and moisture, resulting in pure crude palm oil (CPO).

Process: A series of filtration steps in the palm oil mill plant ensures purity:

Setting & Screening: The oil first passes through clarification tanks and vibrating screens to remove coarse solids and fibers.

Filtration & Drying: It then goes through plate filters to eliminate fine impurities. Finally, a vacuum dryer reduces the moisture content to below 0.2%, producing stable, market-ready CPO.

7. By-Product Utilization

A modern and economical palm oil mill plant focuses on sustainability:

Empty Fruit Bunches (EFB): Used as boiler fuel or organic fertilizer.

Press Cake: Can be processed to extract palm kernel oil, with the residue used as animal feed

If you plan to invest in a new palm oil mill plant or upgrade your existing production line and its palm oil processing steps, please contact Henan Glory. Our professional team is committed to providing you with dedicated assistance.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!