This 1-5t/h small scale palm oil processing machine is designed by Henan Glory, very hot sale in Africa. It can not only reduce the labor cost a lot, but also improve the production efficiency and crude oil quality of small palm oil mill a lot. Now, let's learn more about this compact yet comprehensive system, including its core components and their functions.

Vertical steam sterilizer in this palm oil processing machine production line is used with fruit cages and steam boiler. Compared to traditional boiling for sterilization, it significantly shortens the sterilization time. In addition, this vertical steam sterilizer has been upgraded to an automated hydraulic door, which provides better sealing and a better sterilization effect.

Vertical steam sterilizer

Vertical steam sterilizer

The drum type palm fruit thresher is usually used in palm oil processing machine production line, because when paired with a conveyor, it can complete an automated continuous separation process. Here, the drum type palm fruit thresher is designed into small processing capacity to match our small palm oil line.

Its rotating mechanism gently yet effectively separates the fruits from the empty bunches. The empty bunches are automatically discharged and can be recycled as boiler fuel, while the fruits are conveyed to the next stage.

The drum type palm fruit thresher

The drum type palm fruit thresher

The vertical palm fruit digester in this small line is also designed based on large scale vertical digester. Its unique stirring system design can not only plenty mash the sterilized fruits, maintain a homogeneous pulp temperature and consistency, but also collect palm oil in advance to reduce the working pressure of the oil press below, maximizing the oil extraction rate in the pressing stage that follows.

The vertical palm fruit digester

The vertical palm fruit digester

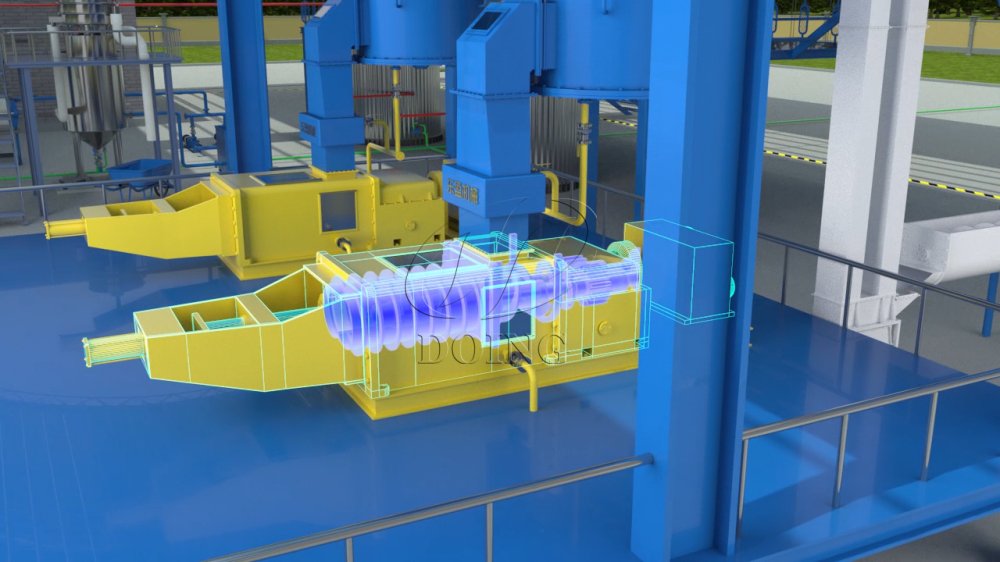

Double screw palm oil presser is the heart of this hot-selling 1-5t/h small scale palm oil processing machine production line. Engineered for superior performance, its double screws apply intense and progressive pressure to the digested pulp, ensuring high oil extraction efficiency. In order to match palm oil processing machine production lines with different processing capacities, we have designed four specifications: 1t/h, 5t/h, 10t/h, and 15t/h.

Double screw palm oil pressers

Double screw palm oil pressers

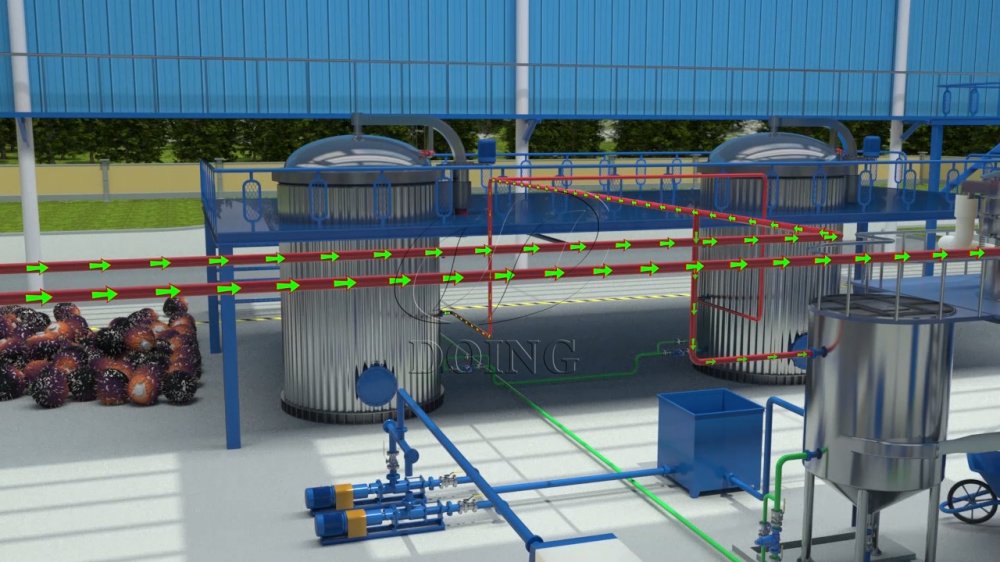

This oil clarification and filtration system is designed for small palm oil processing line. On the basis of the large system, its design retains the functions of the three main devices: vibrating screen to removes large particles impurities, oil clarification tank for sedimentation and plate and frame filter to remove fine residues, resulting in clear, high-quality crude palm oil that meets market standards.

The oil clarification and filtration system

The oil clarification and filtration system

The integrated vacuum drying system is the key innovative feature that sets this 1-5t/h small scale palm oil processing machine line apart. Instead of traditional open-air heating, it uses a vacuum to lower the boiling point of water, gently removing residual moisture from the oil at lower temperatures. This technology preserves oil quality by preventing thermal degradation, effectively reducing oxidation risk and ensuring a longer shelf life for the final product.

The integrated vacuum drying system

The integrated vacuum drying system

In summary, the 1-5t/h small scale palm oil processing machine integrates smart technological innovations across every stage, with excellent extraction rates, combined with reliable performance and ideal capacity, to make it a highly sought-after and best-selling solution in the global market for small scale palm oil production business.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!