This comprehensive medium and large scale palm oil processing machine manufactured by Henan Glory is designed for high-capacity operations of 10 to 120 tons/hour, featuring a highly automated and continuous processing flow, achieving superior efficiency and seamless material handling. As a complete solution, it comes standard with a full kernel recovery station and a professional water treatment station, ensuring sustainable and profitable long-term operation.

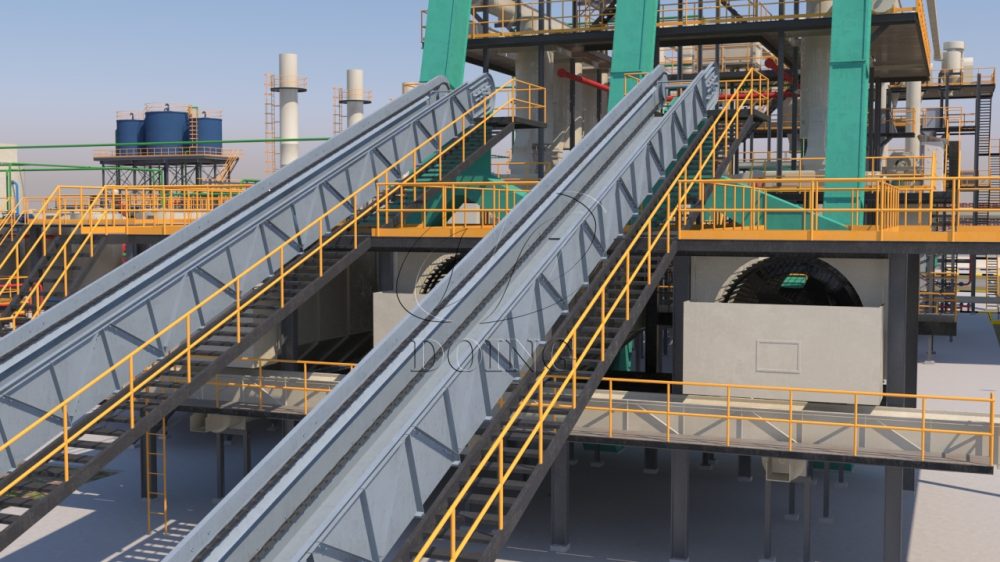

The raw material reception station in this palm oil processing machine production line is equipped with a robust receiving hopper and a highly efficient conveyor system, designed for the high-volume unloading of Fresh Fruit Bunches (FFB). It features a receiving hopper with a hydraulically controlled sliding gate, powered by a dedicated hydraulic unit, which ensures precise and stable feeding of FFB into the scraper conveyor below for continuous transfer to the sterilizers.

The raw material reception station

The raw material reception station

The palm fruit sterilizing station is critical for preserving final oil quality and ensuring efficient processing. Henan Glory offers two types of sterilizers to suit different factory layouts and needs:

(1) Horizontal Sterilizers: Feature an internal trolley system for effective condensate drainage, reducing fruit moisture content and minimizing Free Fatty Acid (FFA) levels in the final oil.

Horizontal sterilizers

Horizontal sterilizers

(2) Vertical Sterilizers: Utilizing a space-saving vertical design, these sterilizers offer high batch capacity (25-30 tons) and a high degree of automation. In a typical 60 t/h palm oil processing machine production line, multiple sterilizers (e.g., four operating plus one standby) work in alternating cycles to ensure uninterrupted production. A bottom drain outlet allows wastewater to be discharged directly for treatment.

Vertical sterilizers

Vertical sterilizers

At the heart of this station is the heavy-duty drum-type thresher with a capacity of 15 t/h. Its horizontal rotating drum gently yet effectively separates sterilized fruits from Empty Fruit Bunches (EFB). In a 60 t/h palm oil processing machine production line, three threshers are standard: two operating in parallel for primary separation, and a third for final separation. Separated fruits are conveyed to pressing, while EFB are expelled for use as mulch, fertilizer, or boiler fuel.

The threshing station

The threshing station

The digester and pressing station is the core of a medium and large palm oil processing machine production line, comprising two key components:

(1) Vertical Digesters: Designed for medium and large scale palm oil processing machine production lines, with each digester having a processing capacity of 4000-5000 liters. It uses internal agitators and direct steam injection to mash fruit into a uniform pulp. A bottom oil outlet pipe allows significant oil recovery prior to pressing, reducing the load on subsequent presses and boosting overall line efficiency.

(2) Continuous Double Screw Pressers: These heavy-duty pressers deliver high mechanical pressure for efficient oil extraction. A hydraulic control system intelligently adjusts the screw gap to maintain optimal performance. In a 60 t/h palm oil processing machine production line, a "four operating, two standby" configuration of 15 t/h pressers ensures continuous operation and easy maintenance. The pressed cake, a mixture of fiber and kernels, is conveyed for kernel recovery.

The digester and pressing station

The digester and pressing station

This station employs a multi-stage, high-capacity clarification system for continuous operation. It includes a primary clarification tank, vibrating screen, large vertical clarification tank, three-phase decanter centrifuge, and sludge oil pit, working in sequence to remove impurities and recover clear oil. The oil is then vacuum-dried, producing high-quality Crude Palm Oil (CPO) with enhanced stability and shelf life, ready for export or refining.

Multi-stage and high-capacity oil clarification system

Multi-stage and high-capacity oil clarification system

The station is equipped with insulated and heated CPO storage tanks, this station maintains the oil at an optimal temperature, preventing solidification and preserving quality during extended storage. This ensures product remains in perfect condition, supporting flexible shipment schedules and downstream processing.

Oil storage station

Oil storage station

A fully integrated and automated system that maximizes by-product value.

(1) Continuous High-Capacity Design: Handles large volumes of mixture of fiber and palm kernel seamlessly.

(2) Multi-Stage Purification: Employs a series of specialized units (cake breaking conveyor, fiber separation column, polishing drum, de-stoning column, kernel grading screen, cracker, air separation column) for efficient, automated kernel cleaning.

(3) Advanced Density Separation: A specialized density separation system using a CaCO₃ solution ensures superior recovery rates of kernels from shell mixtures, maximizing yield.

(4) Centralized Drying & Storage: Kernels are dried to a precise moisture content (typically 4-5%) in a dedicated drying bin, ensuring stability for storage or sale.

Kernel recovery station

Kernel recovery station

Engineered for high efficiency and fuel autonomy, this station distinguishes large-scale operations.

(1) Automated Fuel System: Palm shells are automatically conveyed from storage as primary fuel, with surplus collected for reuse.

(2) Ash & Emission Management: Includes a cyclone for ash handling and a dedicated chimney for compliant emissions.

(3) Centralized Water Management: Beyond standard boiler feedwater treatment, it provides process hot water, firefighting supply, and cleaning lines for the entire plant.

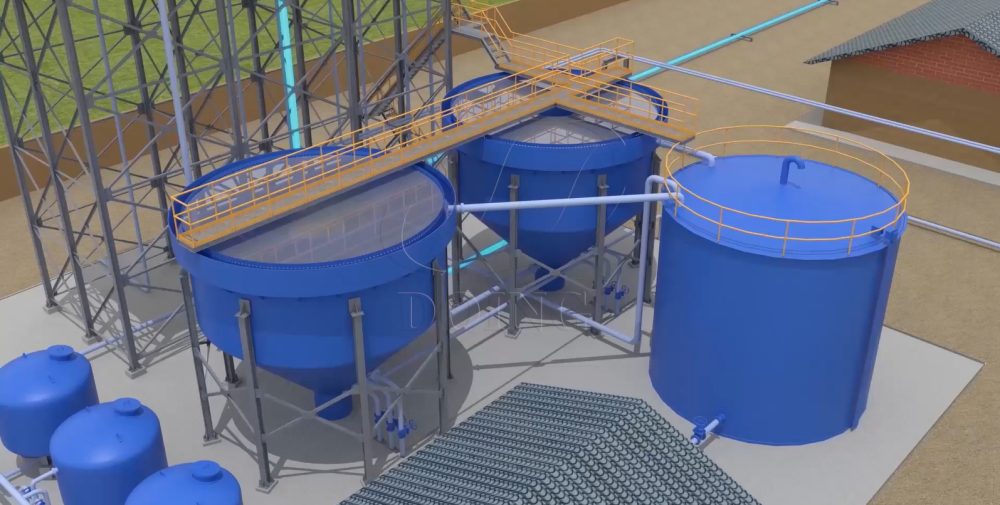

The water treatment station is an essential facility in medium and large scale palm oil processing machine production lines. This self-contained system ensures a consistent and reliable water supply for all plant operations.

(1) Automatic Water Intake System: A pontoon-based system adapts to river level changes for continuous raw water extraction.

(2) Large-Capacity Reservoir: Provides a 20-30 day production buffer.

(3) Integrated Purification: The treatment system incorporates a complete set of dedicated components, including a source water tank, water clarification tank, temporary storage tank, pressure sand filter, and clean water tank, ensuring consistent water quality for various production and auxiliary needs.

(4) Closed-Loop Quality Management: Internal circulation maintains water quality and availability.

Water treatment station

Water treatment station

In conclusion, from raw material reception to final product storage, every component within the Henan Glory processing plant is engineered for seamless integration, high throughput, and long-term reliability. We provide more than machine—our comprehensive service includes plant design, installation, commissioning, and operator training. Contact us to discover how our tailored, high-efficiency solutions can meet your specific production and profitability goals.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!