Henan Glory Company has rolled out a small scale free-installation palm oil processing machine. This innovative solution eliminates complex installation steps – users only need to unpack and assemble the machine to start processing. The 1t/h free-installation palm oil processing machine, our current featured product, consists of three frames.

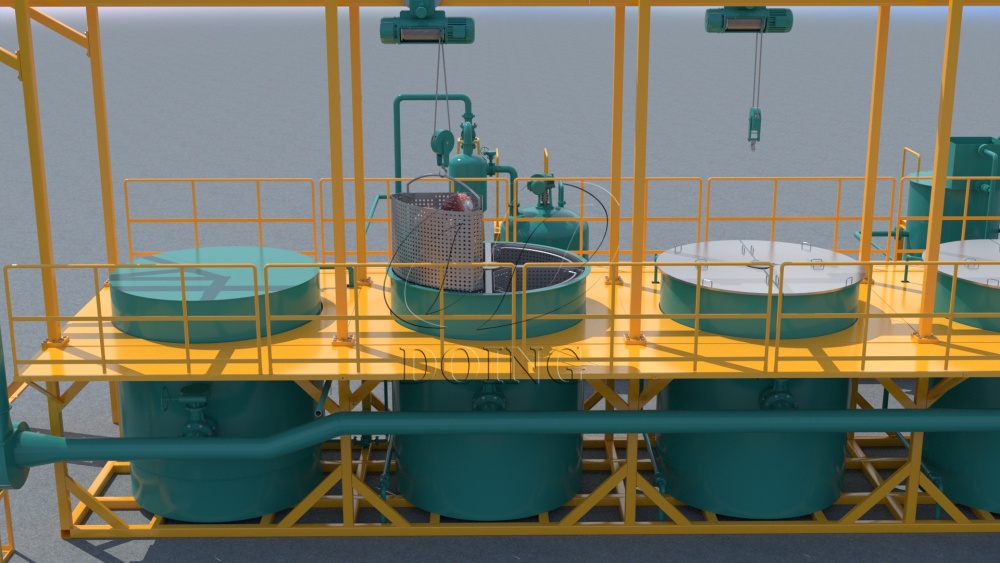

Palm fruit sterilization machine

Palm fruit sterilization machine

This frame is equipped with a hot water tank and three sterilization tanks, ensuring the completion of sterilization for large quantities of palm fruit bunches within the specified time.

The function of the hot water tank is to supply hot water and steam for the production process, with firewood or other biomass fuels that can be directly burned beneath it. This design replaces steam boilers and reduces equipment costs. The upper frame of the three sterilization tanks is fitted with electric hoists; during operation, workers load palm fruit bunches into fruit cages, and the electric hoists then lift and transfer the cages into the sterilization tanks, effectively cutting down manual handling costs. The entire fermentation-killing process lasts for two hours, which aims to soften palm fruits for easier subsequent oil extraction and reduce the content of free fatty acids in the oil, thus ensuring the quality of the final oil product.

Palm fruit thresher and oil presser

Palm fruit thresher and oil presser

This frame includes a thresher and two oil presses. After sterilizing, the palm fruit bunches are lifted again by electric hoists and poured into the feed inlet of the drum-type thresher, which boasts a threshing rate of up to 98%. During rotation, palm fruits fall onto the conveyor belt under the thresher, while empty fruit bunches are discharged from the other end of the drum for workers to collect and use as fuel.

The palm oil processing machine is equipped with our company's 1tph double-screw oil press machine. The press screw of this oil press is made of 2Cr13 wear-resistant alloy steel, ensuring a longer service life. Meanwhile, combined with a hydraulic pump station, it can automatically adjust the chamber pressure to ensure the integrity of palm nuts, featuring a higher level of automation. The detached palm fruits first enter the first oil press for preliminary crushing, and then they are sent to the second oil press for pressing.

Palm oil filtration and drying machines

Palm oil filtration and drying machines

This frame comprises an oil clarification tank, a rotary vibrating screen, a plate filter, and a vacuum dehydration system. The oil clarification tank serves as primary impurity removal equipment, separating heavy impurities such as sand and sediment through gravity sedimentation. The rotary vibrating screen uses a screen mesh to filter suspended fibers, and the plate filter performs fine filtration to trap tiny impurities. The vacuum dehydration system utilizes resistance wire heating in a vacuum environment to rapidly evaporate moisture from crude palm oil, which extends the storage time and also provides stable raw materials for subsequent deep processing. If you have requirements, we can also provide oil storage tanks, which only need on-site welding to be put into use.

These three frames can be respectively loaded into three containers, facilitating transportation. After all equipment arrives at the site, it can be put into production line operation only by simple pipeline and circuit connection.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!