Henan Glory's 5tph small scale full-automatic palm oil processing machine is developed from the mature extraction technology of large scale palm oil mills in Malaysia. It incorporates the core performance strengths of large scale equipment and integrates the flexibility of small scale production, featuring time and labor savings, easy operation, and higher oil yield.

Highlights of 5tph Small Scale Full-Automatic Palm Oil Processing Machine

Automated vertical steam sterilizer

Automated vertical steam sterilizer

Cage-Free Automation: Redesigned from the 1-5t/h palm oil processing machine line's fruit cage structure, integrated with scraper conveyors for direct FFB feeding/discharging—eliminating manual handling and enabling 24/7 continuous operation.

Efficient Heating System: Boiler-driven external heating coils ensure uniform heat distribution, cutting sterilization time to 60-90 minutes; optional PLC control for higher efficiency and cost savings.

Drum type palm fruit thresher

Drum type palm fruit thresher

Efficient Fruit Separation: Rotating drum design facilitates smooth fruit detachment; 2.5m long drum stroke ensures sufficient processing time, preventing premature fruit discharge and achieving higher separation cleanliness.

Automation Compatibility: Seamlessly connects with upstream/downstream conveyors for continuous operation, minimizing labor input.

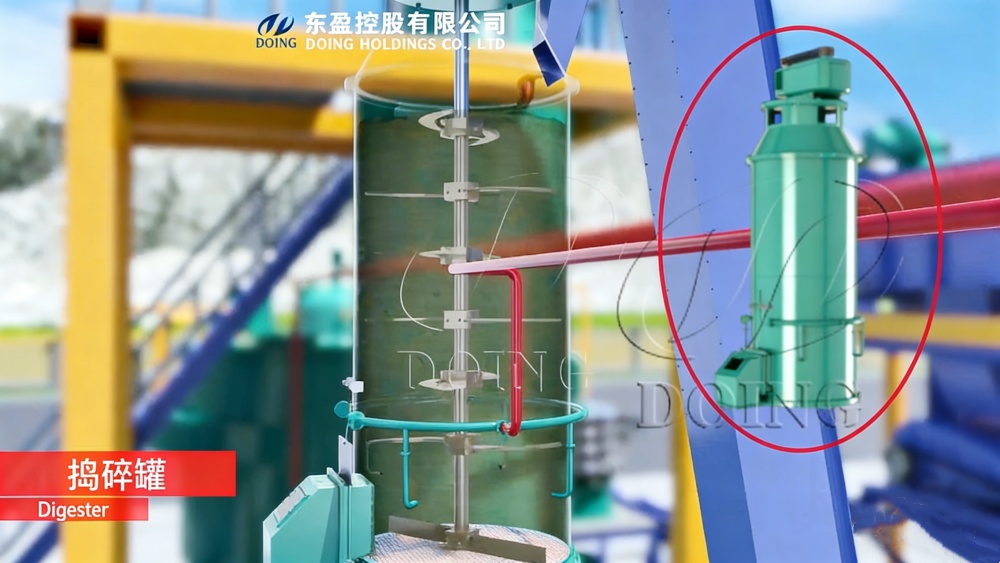

Vertical palm fruit digester

Vertical palm fruit digester

Dual-Function Processing: Vertical structure enhances digesting efficiency; integrated stirring system crushes palm pulp, while external steam coils enable secondary cooking during operation—softening pulp for optimal oil release.

Oil Yield and Machine Protection: Pre-crushing before pressing boosts extraction efficiency and reduces wear on the subsequent oil press, extending equipment lifespan and lowering maintenance costs.

Double screw palm oil presser

Double screw palm oil presser

Multiple Capacity Options: Henan Glory offers four specifications to match diverse production needs: 1t/h, 5t/h, 10t/h, and 15t/h. This 5tph small scale palm oil processing machine line adopts the dedicated 5t/h model for optimal compatibility.

Core Performance Advantages: Double-screw structure design ensures high oil extraction (residual oil rate ≤6% in pressed cake); integrated setup (consistent with large-scale mills) directly below the digester minimizes material loss.

Palm oil clarification machines

Palm oil clarification machines

Targeted Multi-Stage Purification: Vibrating Screen (fine fibers) → Oil Clarification Tank (heavy impurities) → Plate Filter (suspended impurities) ensures crude palm oil meets market-ready standards.

Palm oil vacuum dryer system

Palm oil vacuum dryer system

Efficient Dehydration & Seamless Transfer: Under vacuum conditions, moisture in the palm oil is evaporated by heating coils to ensure thorough drying, and the dried crude oil can be directly transferred to the matched crude oil tank, streamlining the production process.

If you want to set up a full-automatic small scale palm oil processing mill, this 5tph palm oil processing machine line is the best choice. Interested? Contact us, now!

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!