For small scale crude palm oil refining with a capacity of up to 20 tons per day, the batch type crude palm oil refinery plant from Henan Glory offers a reliable and economical solution. Ideal for producers with lower tonnage requirements or those who need to process different types of crude oils in rotation, this plant is designed to be compact, easy to operate, and budget-friendly—without compromising on final oil quality.

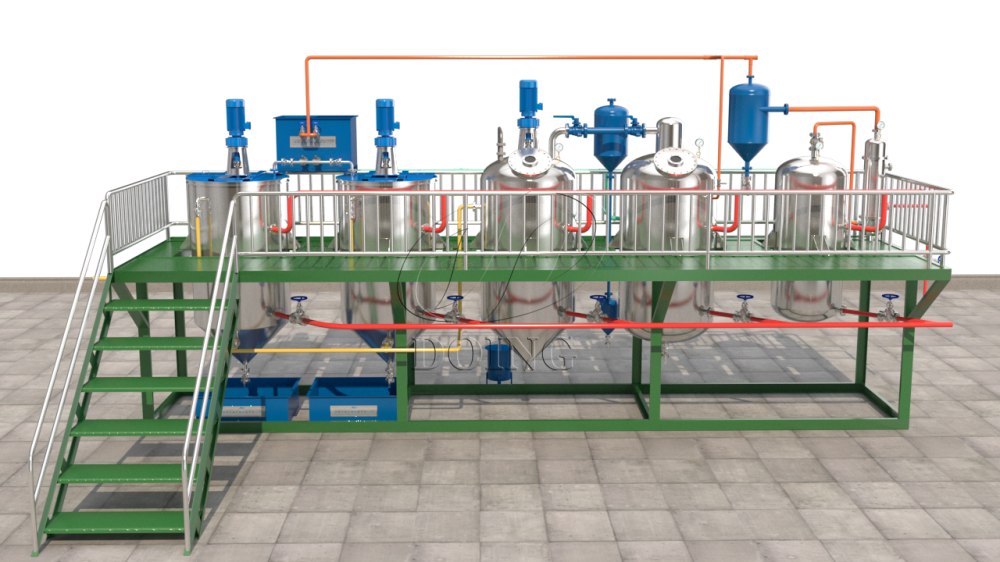

The batch type crude palm oil refinery plant is designed with a rational layout, where equipment is strategically installed both inside and outside the plant for optimal workflow and space utilization.

(1) Refining Tank (Neutralization Tank): Used for degumming and deacidification to remove gums and free fatty acids from crude palm oil.

(2) Decolorization Tank: Eliminates pigments and impurities using adsorbent materials such as bleaching clay, improving oil color and purity.

(3) Deodorization Tank: Odors and volatile compounds are removed and volatile compounds under high-temperature vacuum conditions. Made of food-grade stainless steel, it boasts a long service life and effectively prevents metal ion contamination of oil.

(4) Steam Generator: Supplies high-temperature steam required for the deodorization process.

Indoor equipment of palm oil refinery plant

Indoor equipment of palm oil refinery plant

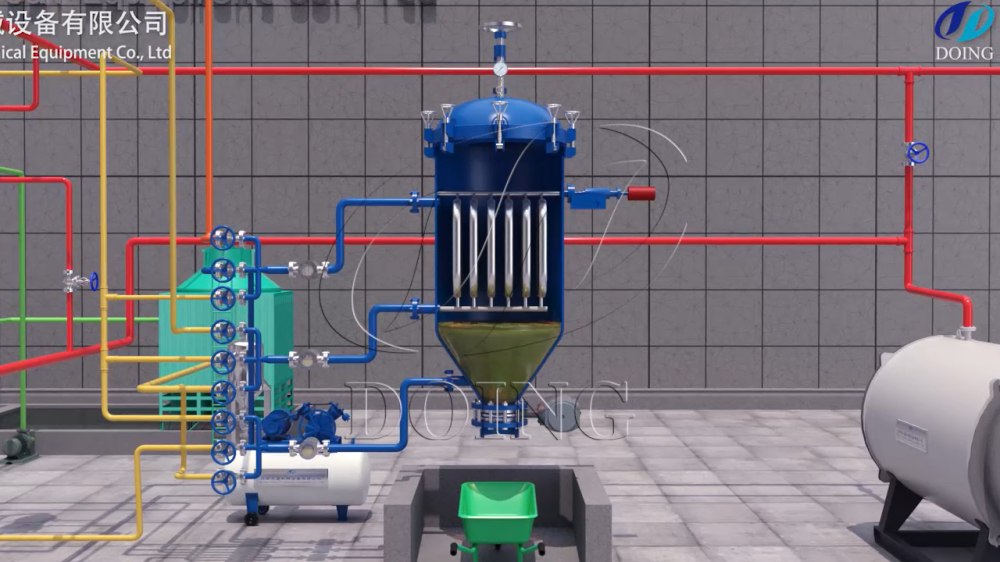

(5) Leaf Filter: Used for efficient filtration of bleaching clay and other solid impurities, reducing oil retention and improving product yield

Leaf filter

Leaf filter

(6) Vacuum Pump: Maintains the necessary vacuum environment for deodorization.

(7) Thermal Oil Heater: Provides consistent and adjustable heat for the entire palm oil refinery process.

Thermal oil heater

Thermal oil heater

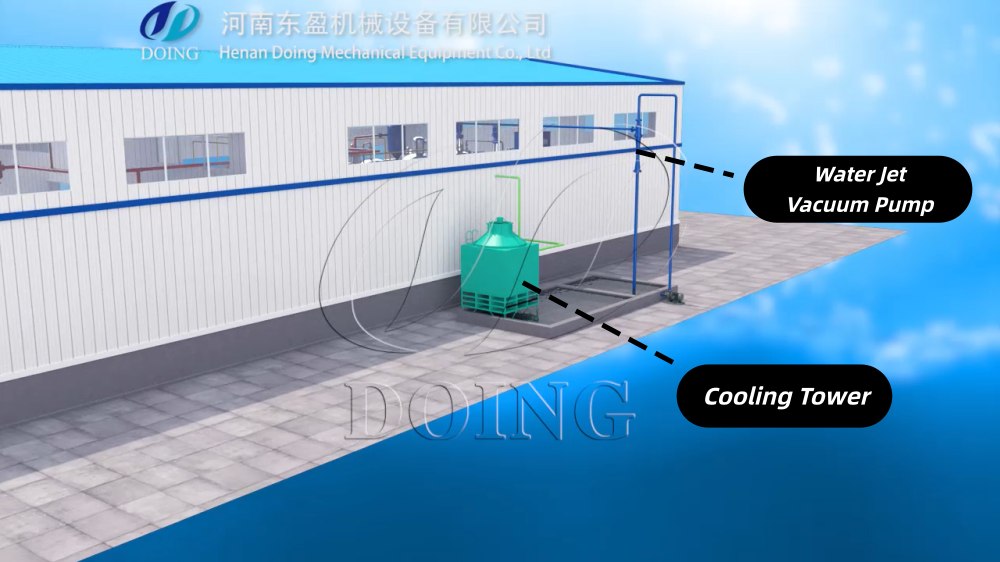

(1) Cooling Tower: Assists in heat exchange and cooling during various palm oil refinery stages.

(2) Water Jet Vacuum Pump: Supports the creation of a vacuum system and is installed outdoors to minimize noise and save indoor space.

Outdoor equipment of palm oil refinery plant

Outdoor equipment of palm oil refinery plant

(1) Small Footprint & Low Building Requirements: Designed for limited spaces, this batch type crude palm oil refinery plant requires minimal installation height and area, making it suitable for small factories or new setups.

(2) Low Investment & Operational Simplicity: With simple equipment structure and straightforward operation, the batch type crude palm oil refinery plant offers an affordable entry into palm oil refining, especially suitable for small-scale operators or those with frequent oil variety changes.

(3) Energy-Efficient Design: The batch type crude palm oil refinery plant emphasizes rational use of thermal energy and reduced utility consumption, helping to minimize operating costs.

(4) Customizable Setup: Equipment selection and layout can be tailored to specific site conditions, budget, and production goals.

(5) Two Heating Options Available: Depending on your local conditions and energy costs, Henan Glory offers two heating systems:

Electric Heating (1-2 t/d): Ideal for small capacities. It uses electric resistance wires to heat the crude oil and requires less investment, but it has high requirements for the stability of local voltage, consumes a lot of electricity, and has high operating costs.

Electric heating palm oil refinery equipment

Electric heating palm oil refinery equipment

Thermal Oil Heating (1-20 t/d): Uses a heat conductive oil stove. Higher upfront cost but more economical for long-term operation.

Thermal oil heating palm oil refinery equipment

Thermal oil heating palm oil refinery equipment

In summary, Henan Glory’ s batch type crude palm oil refinery plant is a smart and practical choice for small and medium processors seeking a flexible, low-investment refining system. Whether you're setting up a new facility or upgrading an existing one, we can provide a batch type palm oil refining solution tailored to your needs. For any further questions, please feel free to contact us for more technical details and support information.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!