Henan Glory provides an advanced 5-30t/d semi-continuous crude palm oil refinery plant that combines the advantages of both batch and full-continuous processes. It adopts batch production for stages such as degumming, deacidification and bleaching, and a continuous deodorizing tower for deodorization—greatly boosting palm oil refining efficiency and resource utilization.

Semi-continuous type crude palm oil refinery plant

Semi-continuous type crude palm oil refinery plant

1) Refining Tank: Used for degumming and deacidification of crude palm oil. It removes gums by adding water; neutralizes FFAs by adding alkali liquor to eliminate impurities.

2) Bleaching Tank: Removes pigments and residual impurities in oils and fats by adding adsorbents (such as activated white clay and activated carbon), improving the color and purity of oils and fats.

3) Leaf Filter: Used for solid-liquid separation of the palm oil mixed with clay in the bleaching tank, thoroughly filtering out spent clay and other impurities to obtain clear palm oil.

4) Deaerator: Before the oil enters the deodorizing tower, it pre-removes dissolved air and moisture, preventing oil oxidation at high temperatures and improving the efficiency of the subsequent vacuum system.

5) Plate Heat Exchanger: A high-efficiency and energy-saving heat exchange equipment. It preheats the cold oil to enter the deodorizing tower by utilizing heat from the high-temperature refined palm oil after deodorization, thereby significantly reducing the system's overall steam consumption.

6) Cooler: Further cools the heat-exchanged refined palm oil to a safe storage temperature, preventing oxidative deterioration from excessive residual heat.

Deodorizing tower

Deodorizing tower

7)Deodorizing Tower: Under high-temperature and high-vacuum conditions, palm oil flows through the tower tray structure, where odorous substances, residual FFAs, and volatile components are removed via steam distillation.

8) FFA Capturer: Used to condenses and recovers volatile substances discharged from the top of the deodorizing tower—primarily high-value palm fatty acids. These can be sold as by-products to generate extra value.

9) Canned Motor Pump: A hot oil transfer pump with an integrated pump-motor structure. Its pump body and rotor are housed together in a sealed device, effectively preventing air ingress during operation.

10) FFA Cycle Tank: Used for temporarily storing FFAs recovered from the capturer and enables their circulation and stable discharge.

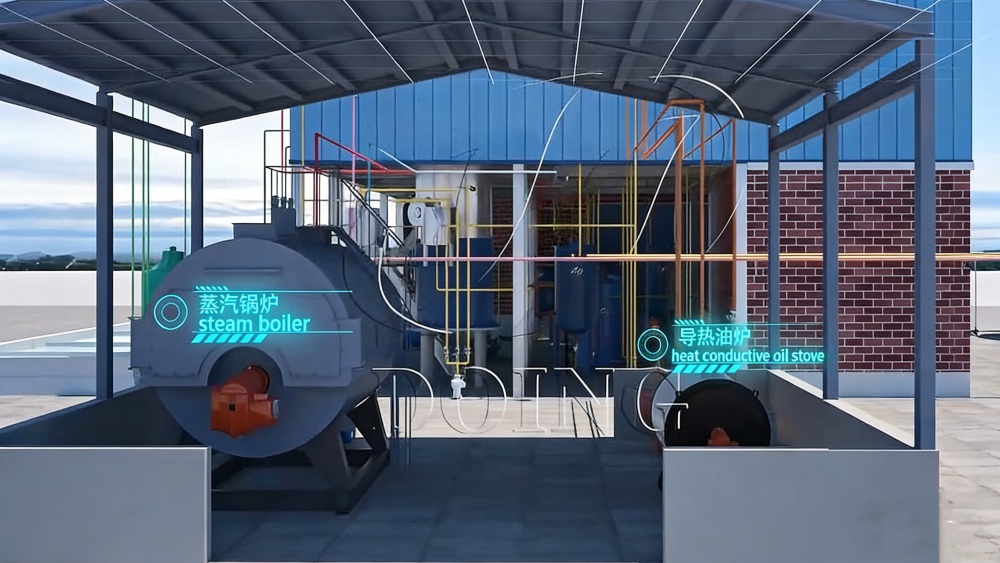

Heat conductive oil stove and steam boiler

Heat conductive oil stove and steam boiler

11)Heat Conductive Oil Stove System: Provides a stable and uniform high-temperature heat source for the entire refining process (especially the deodorization stage), serving as a key guarantee for maintaining process temperature.

12) Steam Boiler System: Supplies direct and indirect steam for the refining tank, deodorizing tower and other equipment, acting as the source of process power and thermal energy.

13)Vacuum System: Creates and maintains a high-vacuum environment for the bleaching and deodorization stages, serving as a core guarantee for preventing oil oxidation, lowering boiling points, and ensuring optimal deodorization results.

1)High Efficiency & Energy Conservation: The deodorization section operates continuously and utilizes high-efficiency heat exchangers for heat recovery, achieving continuous, low-energy consumption operation in the energy-intensive process.

2)Cost-Effective Investment & High Returns: With significantly lower overall palm oil refinery plant costs and operating expenses compared to full-continuous oil refinery plant, coupled with the generation of additional revenue from recovered FFAs. This semi-continuous crude palm oil refinery equipment provides the most cost-effective technical upgrading solution for palm oil refineries.

In summary, Henan Glory's 5-30t/d semi-continuous type crude palm oil refinery plant combines high production efficiency, excellent cost-effectiveness, and reliable performance. If you are interested in this semi-continuous palm oil refining equipment, please feel free to contact us.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!