For palm kernel oil processing enterprises, efficient kernel-shell separation is a critical step to maximizing oil yield. Henan Glory’s engineered palm kernel cracker and separator machine consists of 5 core units, available in two processing capacities: 2–3tph and 4–6tph. Below is a detailed breakdown of each machine’s functions, working principles and unique advantages.

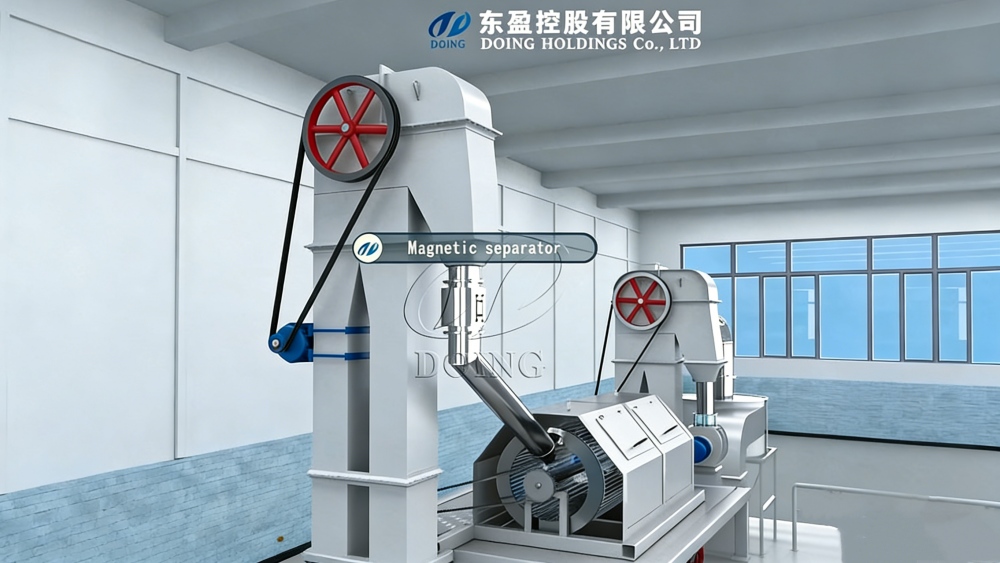

Core Function: Preprocess raw palm nuts before cracking to remove iron filings, small metal scraps and other impurities.

Working Principle: Adopts high-intensity magnetic adsorption technology. As raw palm nuts pass through magnetic separator, metallic impurities are firmly captured by the strong magnetic field, while non-magnetic palm nuts flow smoothly into the next stage.

Core Advantages:

1) No moving parts result in low failure rates and easy maintenance.

2) Eliminates metal-induced damage to key components such as cracker rotors and toothed walls from the source, reducing equipment maintenance costs.

Magnetic separator

Magnetic separator

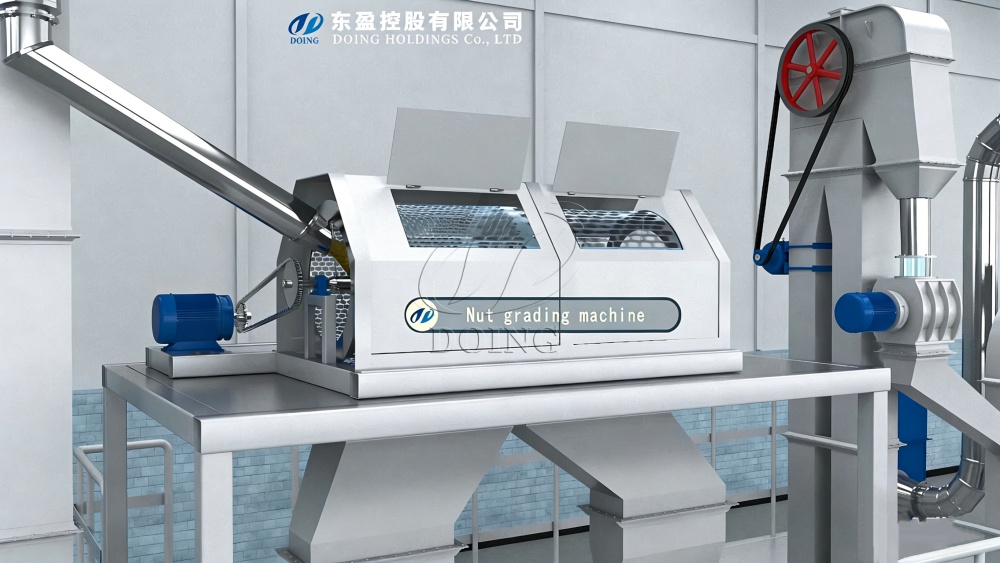

Core Function: Classify palm nuts by particle size for precise screening.

Working Principle: Equipped with precision sieves of varying mesh sizes. When raw palm nuts fall onto the sieve surface, vibration and gravity drive nuts of different sizes into designated discharge outlets. The graded palm nuts are then conveyed to two crackers respectively.

Core Advantages:

1) Ensures uniform nut size for subsequent cracking processes, preventing under-cracking of small nuts and over-crushing of large ones.

2) Optimizes palm nut cracking conditions: processing nuts of similar specifications in batches significantly improves overall cracking efficiency.

3) Eliminates the need for manual sorting and reduces labor costs.

Palm nut grading machine

Palm nut grading machine

Core Function: Break the hard outer shell of palm nuts to extract intact, oil-rich kernels inside.

Working Principle: Adopts the principle of high-speed centrifugal impact. The beating bars (rotor) inside the machine rotate at high speed, driving palm nuts to collide with the rotor and the internal toothed wall of the machine.

Core Advantages:

1) The gap between beating bars and the toothed wall is adjustable according to nut size and hardness, allowing precise control of impact force. This achieves shell-breaking without kernel damage.

2) Boasts a cracking rate of 95%–98% with minimal kernel breakage, laying a solid foundation for maximizing oil yield in subsequent pressing process.

Palm nut cracker

Palm nut cracker

Core Function: Conduct primary kernel-shell separation of cracked materials.

Working Principle: Separates kernels from shells based on their density difference. A uniform upward airflow is generated at the bottom of the column: lightweight shell is lifted by the airflow, while dense kernels fall vertically into the collection hopper for further processing.

Core Advantages:

It is equipped with a transparent sight glass, enabling operators to visually monitor the separation effect in real time. This facilitates timely adjustment of airflow parameters to maintain consistent separation performance.

Wind separation column

Wind separation column

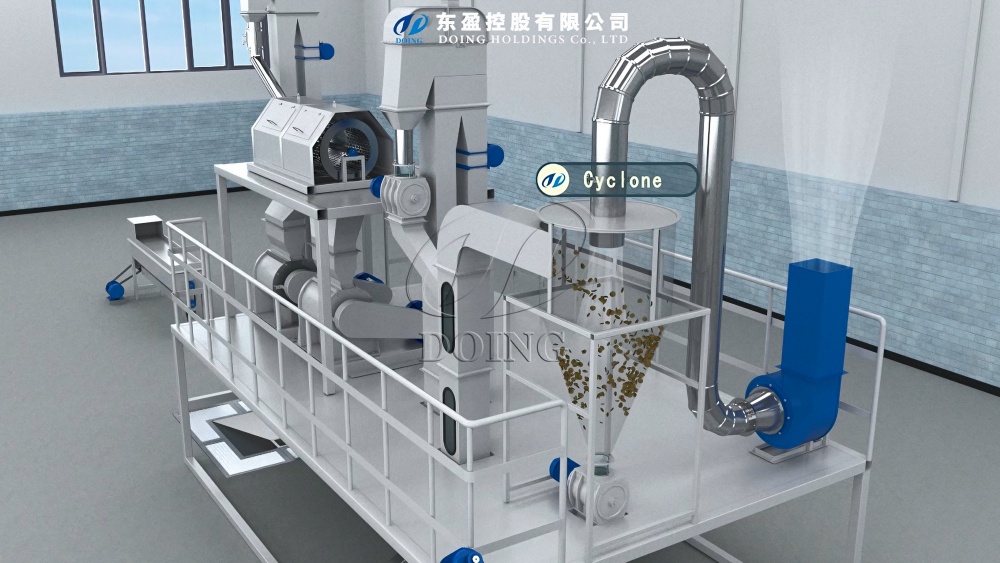

Core Function: Perform deep kernel-shell separation of materials.

Working Principle: Features a cylindrical-conical structure and is connected to a blower. Airflow containing shells enters the chamber, forming a downward rotating airflow that pushes shell residues out through the bottom for collection.

Core Advantages:

1) Collects shell debris to maintain workshop cleanliness.

2) The recovered palm shells can be used as biomass fuel.

Cyclone separator

Cyclone separator

1) Achieves an overall separation rate of 99%, ensuring minimal shell content in kernels fed into the pressing process.

2) Adopts dry separation technology with zero wastewater discharge, meeting green environmental standards and eliminating the need for post-separation kernel drying.

3) Simple structure ensures low operational costs

4) Collected shell can be used as boiler fuel, achieving full resource recycling.

Is this high-efficiency palm kernel cracker and separator machine exactly what you need? For a quote, technical specifications or customized solutions, feel free to contact us anytime!

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!