Henan Glory presents its robust and highly efficient palm kernel oil presser, a core machine meticulously engineered for extracting high-quality oil from palm kernels. Designed by our expert engineers, this palm kernel oil presser combines durable construction with intelligent mechanical principles to deliver superior performance, making it a critical component for modern palm kernel oil mill plants.

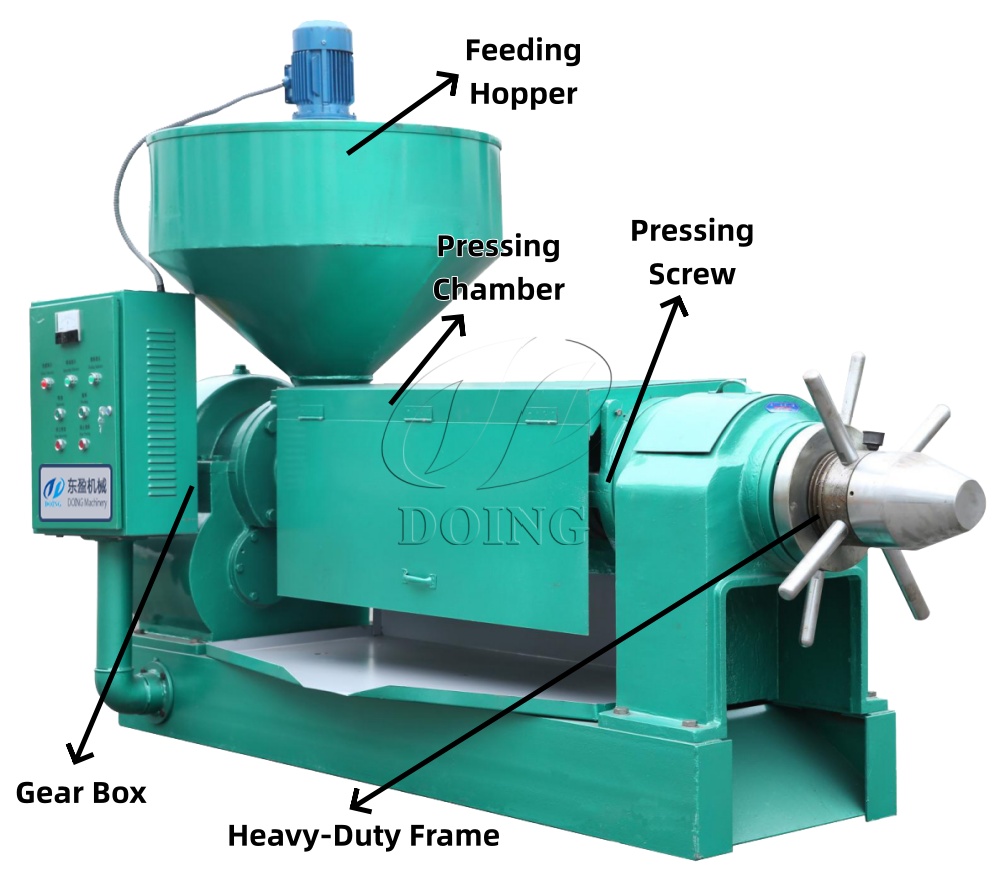

The palm kernel oil presser is built around five key structural parts, ensuring reliability and ease of maintenance:

(1) Feeding Hopper: For controlled and continuous palm kernels input.

(2) Gear Box: Houses a high-precision gear system to deliver optimal torque and speed.

(3) Pressing Chamber: The high-strength cylinder where extraction occurs under intense pressure.

(4) Pressing Screw: The heart of the palm kernel oil presser, featuring a uniquely designed, wear-resistant screw with a progressively increasing root diameter.

(5) Heavy-Duty Frame: Provides exceptional stability and vibration-free operation during continuous high-load operations.

Core components of palm kernel oil presser

Core components of palm kernel oil presser

| Parameter | Specification |

| Capacity (kg/h) | 500 |

| Main Power (kw) | 30 |

| Shaft Speed (r/min) | 35-39 |

| Weight (kg) | 960 |

| Size (mm) | 2020*700*1480 |

| Gear Ratio | 115/38*15/52 = 1:8.78 |

The palm kernel oil presser operates on a continuous, high-pressure mechanical principle:

(1) Feed & Compression: Conditioned palm kernels are fed into one side of the palm kernel oil presser, entering the pressing chamber. A heavy-duty, specially designed worm screw rotates, simultaneously moving the material forward and subjecting it to increasing mechanical pressure and internal friction.

(2) Oil Separation & Collection: Under this immense pressure, the oil cells are ruptured, releasing the oil. The crude palm kernel oil seeps out through precisely sized micro-openings in the cage bars. These openings are designed to allow only the liquid oil to pass through, effectively preventing solid meal residues from contaminating the extracted oil, which collects in a trough.

(3) Cake Discharge: The solid residue, now formed into firm palm kernel cake (PKC), is discharged from the opposite end of the palm kernel oil presser, completing a continuous and efficient cycle.

Palm kernel oil presser

Palm kernel oil presser

(1) High Oil Yield & Quality: Achieves exceptional extraction rates, producing clear, pure palm kernel oil with preserved natural properties. The efficient pressing action reduces oil loss in the meal.

(2) Robust Construction: Fabricated from high-grade alloy steels and critical wear parts, the palm kernel oil presser is built to withstand continuous heavy-duty operation with minimal maintenance downtime.

(3) Advanced Conditioning System: Integrated heating capabilities allow for optimal temperature control during pressing, which is crucial for adjusting oil viscosity and maximizing extraction efficiency from palm kernels.

(4) Energy-Efficient Operation: Designed with an optimized drive system to deliver high output per unit of power consumption, reducing overall operational costs.

(5) User-Centric Design: Features include adjustable choke mechanisms for process control, easy disassembly for cleaning and maintenance, and safety guards.

(6) Durable Cake Discharge: Produces a well-formed, dry palm kernel cake (PKC) suitable for use as valuable animal feed or biomass fuel.

This 500 kg/h palm kernel oil presser is the core of an efficient palm kernel oil extraction line. Henan Glory provides complete solutions, typically including: Polishing Drum/Fiber Separator → Kernel & Shell Separation System → Crusher → Cooker → Presser → Plate Filter. We specialize in designing cost-effective plants for small, medium to large capacity, ensuring optimal layout and equipment synergy.

Efficient palm kernel oil extraction line

Efficient palm kernel oil extraction line

From supplying the core palm kernel oil presser to designing complete palm kernel oil processing lines, Henan Glory Company is committed to providing not just equipment, but practical, cost-effective solutions backed by comprehensive technical support, installation guidance, and after-sales service. Contact us to discuss your specific requirements. Our engineering team is ready to help you design and build a profitable palm kernel oil processing plant.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!