This production line integrates mechanical pre-pressing and solvent extraction processes, and reduces the residual oil rate to ≤1% via high automation, enabling maximum oil extraction from high-oil-content (50-55%) palm kernels. Designed specifically for large-scale oil mills with a daily processing capacity of 30-600 tons, it aims to maximize your oil revenue.

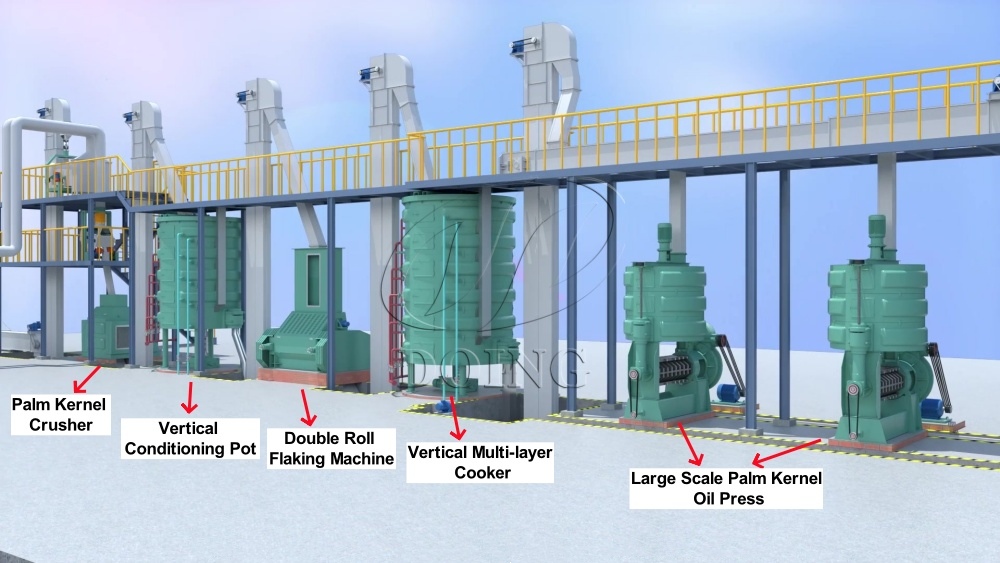

Palm kernel oil pre-pressing equipment

Palm kernel oil pre-pressing equipment

Palm Kernel Crusher

Structural Design: Adopts a double-pair roller extrusion structure with adjustable roller gaps for better crushing performance.

Design Advantages: Prevents over-crushing or uneven fragmentation, ensuring the raw material is uniformly broken into 6-8 segments. It also reduces the load and wear on the oil press, extending the equipment's service life.

Vertical Conditioning Pot

Structural Design: Features a multi-layer + spiral stirring structure, connected to pipelines for steam and water injection to adjust the elastic-plasticity of palm kernels.

Design Advantages: Ensures uniform heating and thorough material mixing, with precise temperature and moisture control to avoid local overheating or uneven moisture, providing stable-condition palm kernels for subsequent processing.

Double Roll Flaking Machine

Structural Design: Equipped with high-hardness alloy toothed rollers, whose gap can be fine-tuned to 0.2-0.5mm.

Design Advantages: The toothed rollers' biting force matches the hardness of palm kernels, enabling high-efficiency rolling and uniform thin flake thickness. The flakes achieve the effect of no oil leakage, firmness when held, and looseness when released.

Vertical Multi-layer Cooker

Structural Design: Features a five-layer vertical structure with clearly defined functional zones: the first layer is the moistening layer, the second and third are steaming layers, and the fourth and fifth are dewatering roasting layers.

Design Advantages: Through precision layer-structured design, the "moistening-steaming-dewatering" process for palm kernel conditioning is ensured to be complete and continuous. With a processing duration of 90 minutes, it facilitates the full aggregation of oil within palm kernels, laying a solid foundation for maximizing oil yield and optimizing oil quality.

Large Scale Palm Kernel Oil Press

Structural Design: Equipped with an auxiliary cooker (with heating and stirring devices) above the press, connected to the press’s feeding port to form an integrated structure with the pressing chamber.

Design Advantages: Takes over the material after layered steaming and roasting, and optimizes the pressing condition of palm kernel material via 30 minutes of temperature and moisture conditioning. This prevents temperature and moisture loss during material conveying, improving the pressing oil yield.

Leaf filter

Leaf filter

At this stage, you have initially extracted palm kernel oil. The pressed crude palm kernel oil enters a leaf filter to remove fine impurities, then is pumped into a palm kernel oil storage tank. The palm kernel pre-pressed cake (with 13%-15% residual oil) is discharged from the tail of the oil press and collected for further residual oil extraction in the solvent extraction workshop.

It is important to note that the extraction solvent (n-hexane) utilized in the solvent extraction process is classified as a flammable and explosive substance. Therefore, the extraction workshop must be designed as an explosion-proof facility.

The solvent extraction process is divided into four sections: solvent extraction, desolventizing, miscella evaporation & stripping, and solvent condensation & recovery. Each section is equipped with dedicated professional equipment.

Rotary-Type Extractor

Rotary-type extractor

Rotary-type extractor

Structural Design: Composed of inner/outer cylinders and partitions to form 12-24 independent extraction cells. Solvent spray nozzles above extractor spray n-hexane solvent to soak the palm kernel pre-pressed cake.

Design Advantages: Simple structure, reliable operation, and built-in filtration of the fixed material layer, resulting in low foam in the miscella and stable extraction performance. It is suitable for continuous production in medium-to-large palm oil mills.

In addition to the rotary-type extractor, we also provide two extractors for large scale palm kernel oil production lines with a daily processing capacity of several hundred tons:

Loop Type Extractor: Uses an loop-type shell + drag chain structure to flip the material layer, ensuring high extraction uniformity, short processing time, and low residual oil rate.

Drag Chain Extractor: Adopts an integrated box structure with lower equipment height and easier installation. Its residual oil rate can reach 0.6%-0.8%, making it a cost-effective choice for large-scale production lines.

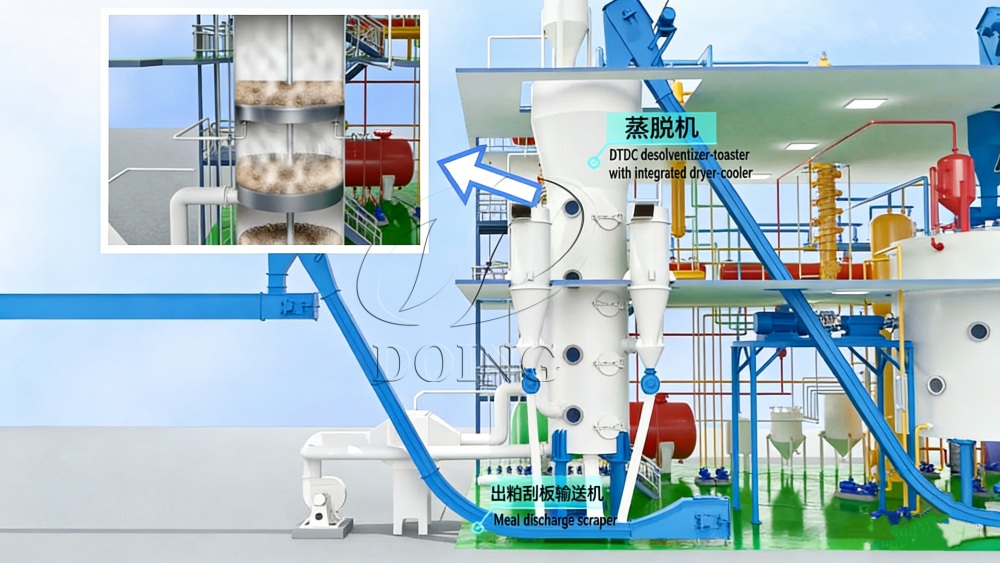

Toaster (DTDC system)

Desolventizer-toaster with integrated dryer-cooler

Desolventizer-toaster with integrated dryer-cooler

Structural Design: Features five functional zones: pre-desolventizing layer, desolventizing layer, direct steam layer, hot air layer, and cold air layer.

Design Advantages: It integrates desolventizing, drying, and cooling, with high steam utilization and stable processing performance. The pre-desolventizing layer reduces steam consumption and condensed moisture in the meal; the direct steam layer achieves deep solvent removal by steam penetrating the material layer; the hot air layer reduces meal moisture to below 13%; the cold air layer cools the meal to around 40℃ for storage.

Raising Film Evaporator & Stripping Tower

Raising film evaporator and stripping tower

Raising film evaporator and stripping tower

Structural Design: Equipped with two evaporators (using indirect steam) to evaporate part of the solvent. The stripper adopts a falling-film multi-layer structure: miscella enters the tower from the top and flows downward, and indirect/direct steam is used for final solvent removal from the miscella in each layer.

Design Advantages: Stepwise solvent removal via indirect steam evaporation and direct steam stripping ensures high heat exchange efficiency, excellent desolventizing performance, and low oil loss.

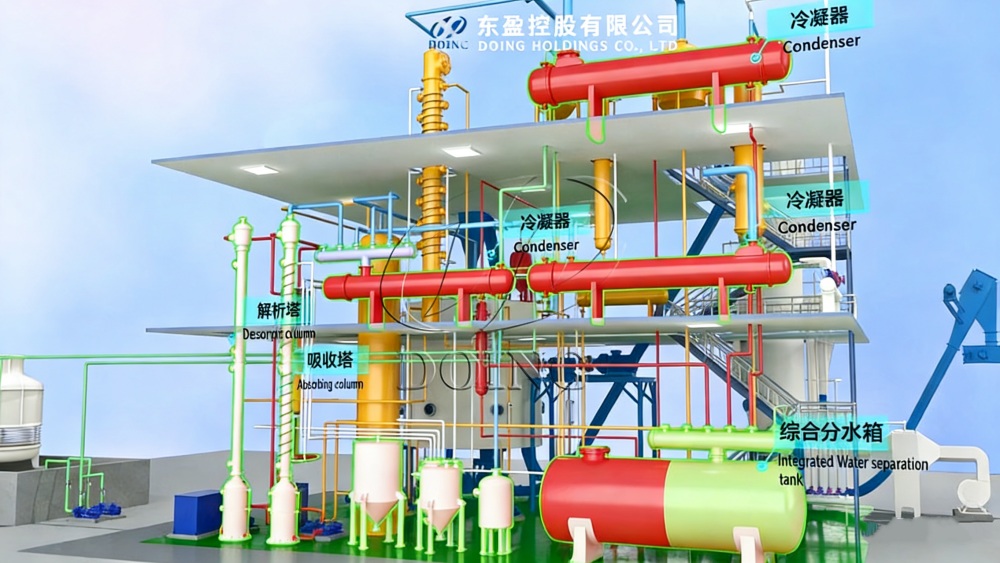

Full-Process Solvent Recovery Equipment

Condenser and integrated water separation tank

Condenser and integrated water separation tank

Structural Design: Equipped with horizontal/vertical condensers (adaptable to different site layouts) and a solvent and water separator (utilizing density differences between solvent and water) to recover solvent vapor generated during miscella evaporation, stripping, meal desolventizing and toasting processes.

Design Advantages: The combination of high-efficiency condensers and water separators achieves high solvent recovery rates, reducing production costs while ensuring production safety and environmental compliance.

In summary, this large scale palm kernel oil pre-pressing and solvent extraction plant integrates core advantages such as high efficiency, large processing capacity, and low residual oil rate, which can significantly improve oil yield and economic benefits. If you wish to learn more about the detailed configuration and investment plan of this large scale palm kernel oil processing plant, please feel free to contact us at any time. Our expert team will provide you with professional answers and customized services.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!