Henan Glory's medium scale palm kernel oil pressing plant (10-30 t/d) is designed specifically for medium-sized producers who are expanding to achieve commercial production, representing a significant upgrade from small scale palm kernel oil pressing plants. The plant employs more advanced pretreatment processes, more refined kernel-shell separation technology, a more comprehensive automation system, thereby significantly improving production efficiency, reliability, and oil yield.

Based on the initial state of the palm kernels, Henan Glory offers two targeted cleaning equipment solutions for your selection:

Palm Kernel Fiber Separator / Polishing Drum: This equipment is equipped with a unique rotating drum that efficiently and mechanically wears away and removes fibrous impurities adhering to the surface of the palm kernels, preparing them for the subsequent shelling process.

Palm kernel fiber separator

Palm kernel fiber separator

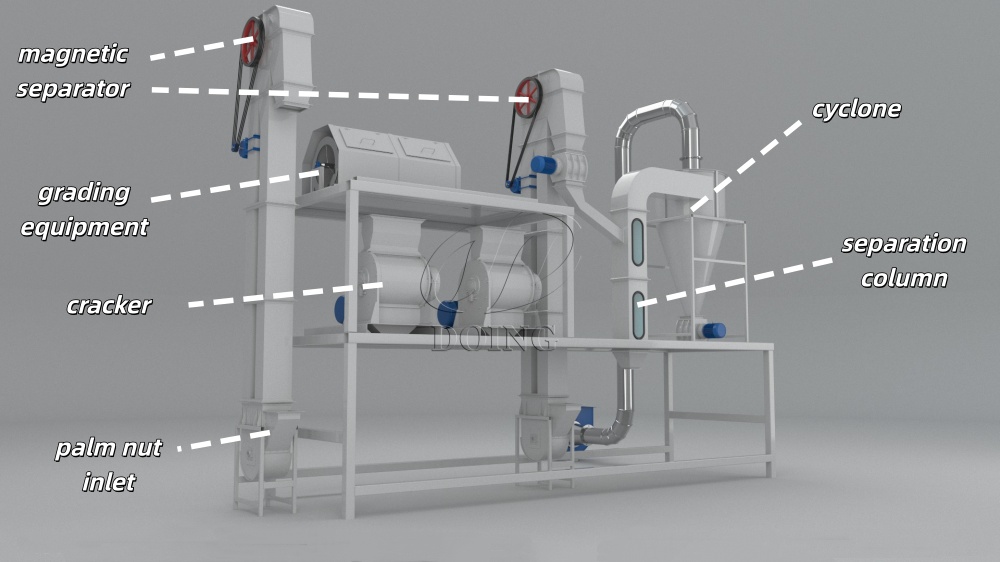

Palm Kernel Shell Crushing and Separation Equipment: It is the core cleaning equipment. Medium scale palm kernel oil pressing plants are typically equipped with a palm kernel shell crushing and separation equipment with a capacity of 4-6 tons/hour. It integrates efficient shelling and automatic sorting functions. Its built-in magnetic separator actively removes ferromagnetic metals, providing crucial protection for all downstream equipment (such as crushers and pressers), extending the overall service life of medium scale palm kernel oil pressing plants. In addition, a palm kernel grading equipment with screens of different mesh sizes can sort palm kernels by size, ensuring uniform feeding into the shelling machine, thereby achieving optimal shell crushing effect and minimal kernel breakage rate, directly improving kernel recovery rate. More importantly, the coordinated wind separation column and cyclone separate the palm kernel and shell mixture based on differences in weight and aerodynamic characteristics, ensuring that the final product is clean, high-quality palm kernels for pressing.

Palm kernel shell crushing and separation equipment

Palm kernel shell crushing and separation equipment

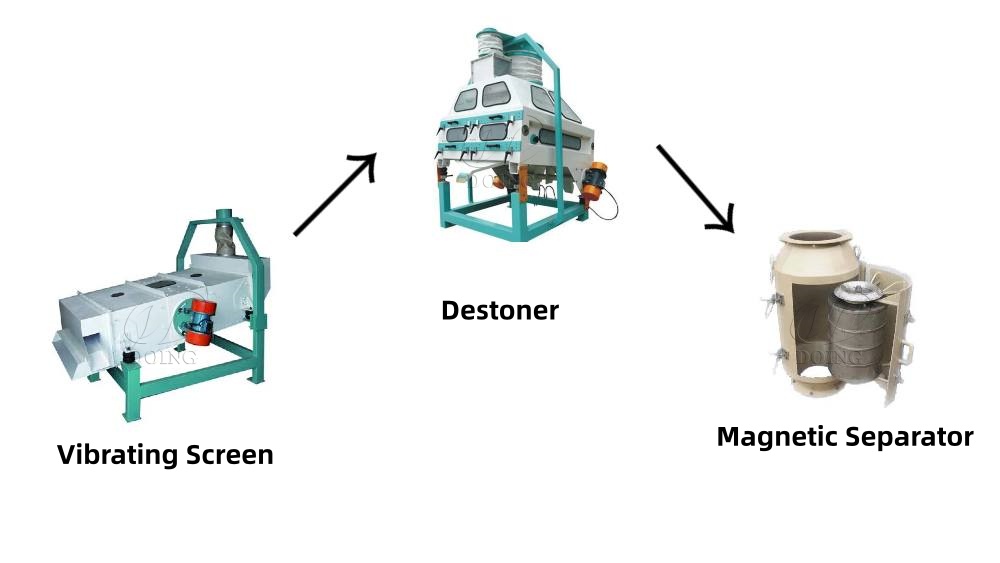

Vibrating Screen: This equipment uses a vibrating motor to drive the screen body, causing the palm kernels to jump and move forward on the screen surface, effectively removing fine dust, debris, and other light impurities mixed in during storage and transportation.

Destoner: Utilizing a combination of air power and vibration, this equipment is specifically designed to remove heavier impurities such as stones and mud that are similar in density to palm kernels but more elastic, ensuring the purity of the palm kernels.

Magnetic Separator: Designed to protect downstream equipment, it generates a strong magnetic field that can 100% adsorb and remove any metal impurities such as nails and screws that may be trapped in the palm kernels, effectively preventing damage to the crusher and presser.

Palm kernel cleaning equipment

Palm kernel cleaning equipment

Heavy-duty Double Roller Palm Kernel Crusher: This crusher is powerful and has stable performance. It employs a double-roller design to crush hard palm kernels into fine, uniform particles. Its robust structure ensures stable operation and minimal maintenance, providing ideal particle size for subsequent processing stages.

Vertical Softening Pot: This vertical structure uses indirect steam in a jacket to regulate the temperature and moisture of the crushed palm kernel particles. Its vertical design allows for a smaller footprint for the same processing capacity and provides uniform conditioning, making it an economical and practical choice for medium scale palm kernel oil pressing plants.

Roller-Type Flattening Mill: This equipment uses a pair of finely polished, high-strength rollers to crush softened granular palm kernels into thin flakes. This process thoroughly breaks down the cellular structure of the palm kernels, forming uniform flakes and significantly increasing the surface area. Our flattening machine is precisely designed to ensure consistent flake thickness and achieve high output.

Palm kernel pre-treatment equipment

Palm kernel pre-treatment equipment

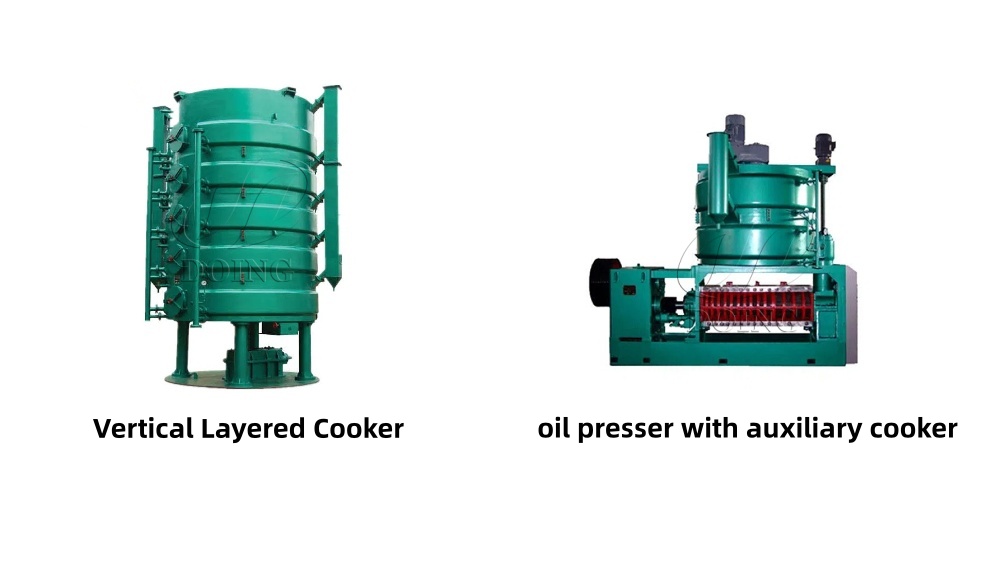

Vertical Layered Cooker: This equipment is the core of the palm kernel heat treatment process. The cooker is typically designed with a five-layer structure, each layer serving a specific function: the first layer is for steam introduction, the second and third layers for steaming the palm kernels, and the fourth and fifth layers for drying and roasting them. It aims to precisely regulate the temperature and humidity of the flakes to ensure they achieve ideal plasticity and elasticity, thereby maximizing oil yield during pressing.

Palm kernel oil presser (with auxiliary cooker): This equipment is a high-efficiency pressing device specifically designed for medium scale palm kernel oil pressing plants. Its core components are a high-strength pressing screw that has undergone special heat treatment and a wear-resistant pressing cage. It comes with an auxiliary cooker, which allows for final temperature and moisture adjustments to the palm kernels before it enters the pressing process, ensuring it always enters the pressing stage in optimal condition. Typically, a single equipment has a large processing capacity, low labor intensity, high oil yield, and produces thin, easily crushed cakes. To meet production capacity, medium scale palm kernel oil pressing plants usually operate two such equipment in parallel.

Vertical layered cooker and oil presser

Vertical layered cooker and oil presser

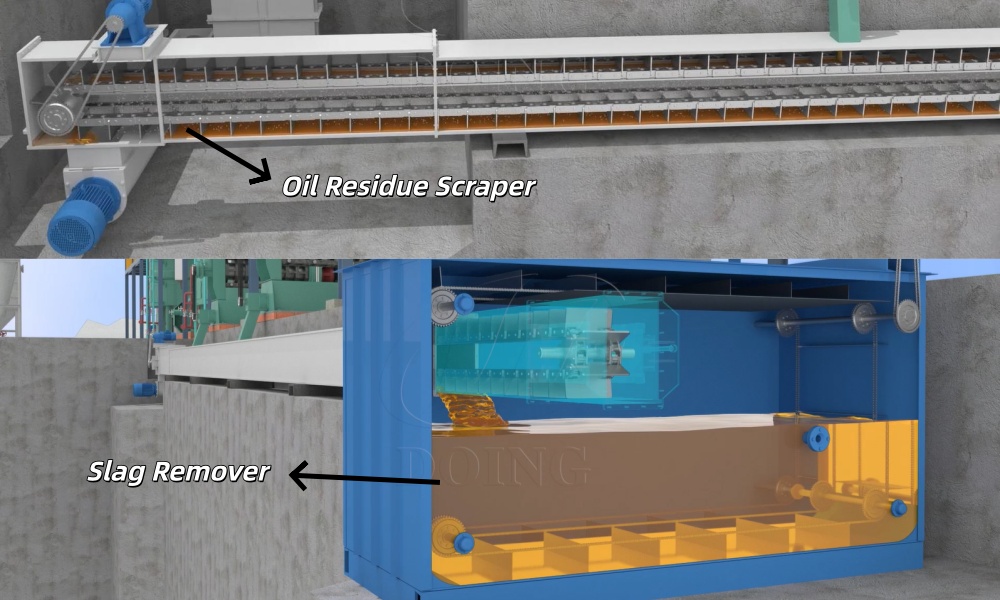

Oil Residue Scraper and Slag Remover: This system is specifically designed for the initial separation of solid cake residue (commonly known as "oil residue") from crude palm kernel oil. Manufactured with corrosion-resistant materials and a reinforced frame, its core component is a series of hardened steel scrapers mounted on a durable scraper chain. Its simple and efficient structure ensures reliable operation and extremely low maintenance.

Oil residue scraper and slag remover

Oil residue scraper and slag remover

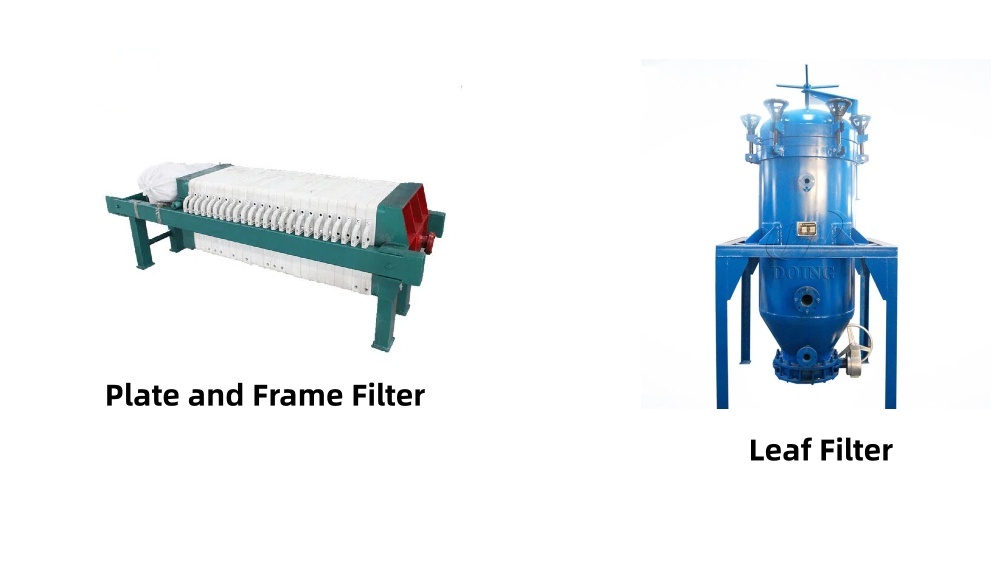

Plate and Frame Filter/Leaf Filter: The core component of this plate and frame filter consists of a series of filter plates and frames mounted on a heavy-duty steel frame, forming multiple filtration chambers. Furthermore, the leaf filter uses vertically installed filter blades. Both configurations utilize specially formulated filter cloth as a precise screening medium, ensuring stable filtration performance and high flow rates. Furthermore, they are constructed from high-grade materials compatible with food processing, equipped with corrosion-resistant filter plates and a reinforced structural frame. This robust structure guarantees long-term reliability, ease of cleaning, and the ability to withstand repeated high-pressure filtration cycles, making it a reliable guarantee for maintaining the final oil quality standards.

Plate filter and leaf filter

Plate filter and leaf filter

In conclusion, each piece of equipment in the above-mentioned medium scale palm kernel oil pressing plant has been carefully designed and selected to provide you with stable and efficient palm kernel oil production. If you are interested in any of palm kernel oil processing equipment or the overall solution, please contact Henan Glory for more detailed technical information.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!