What are the basic equipment needed for a palm oil commercial production?

Commercial palm oil production involves a series of specialized processes, from harvesting fresh palm fruit bunches to packaging the finished product. Each stage relies on specific equipment to ensure efficiency, quality, and compliance with industry standards. Below, Henan Glory Company will introduce the basic equipment needed for a palm oil commercial production, covering both pressing and refining processes, as well as supporting equipment.

I. The Basic Equipment Needed for Palm Oil Pressing Production Line

1. Palm Fruit Harvesting Equipment

-Harvesting knives: Used to cut palm fruit bunches from the trees.

-Climbing tools: Safety harnesses and climbing tools allow workers to reach high bunches on tall palm trees.

2. Fruit Transport Equipment

-Carts or trucks: Transport palm fruit bunches from the plantation to the palm oil processing plant.

-Scraper conveyor and bucket elevator: Move fruit bunches or separated fruits between processing stages (e.g., from unloading to sterilizing), optimizing workflow in commercial palm oil production.

3. Sterilizing Equipment

Sterilizer: The sterilizer use direct steam at 300 KPa to heat palm fruits at high temperatures for about 60 minutes. This destroys enzymes in the palm fruits, avoiding the increase of FFA content in the oil. The high temperature will also make the fruits soften, making it easier to thresh the fruit in commercial palm oil production.

Palm fruit sterilizing and threshing equipment

Palm fruit sterilizing and threshing equipment

4.Threshing Equipment

Thresher: A drum type thresher separates palm fruits from the bunches. The separated palm fruits are sent to the next processing stage, while the empty bunches are transported to the boiler for fuel, aligning with cost-efficient commercial palm oil production.

5. Digesting Equipment

Digester: The digester is equipped with stirring arms inside, under the driving of the top motor, to crush the palm fruits. Direct steam is injected into the digester to boil the palm fruit, making it easier to extract oil in commercial palm oil production.

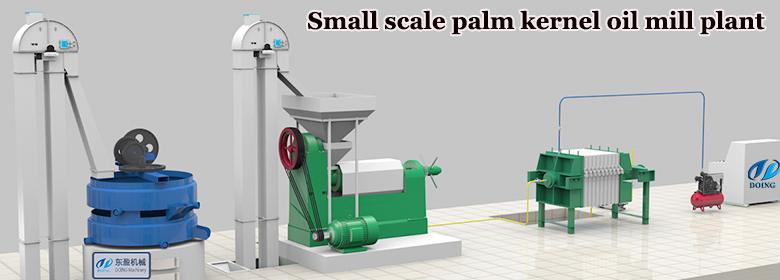

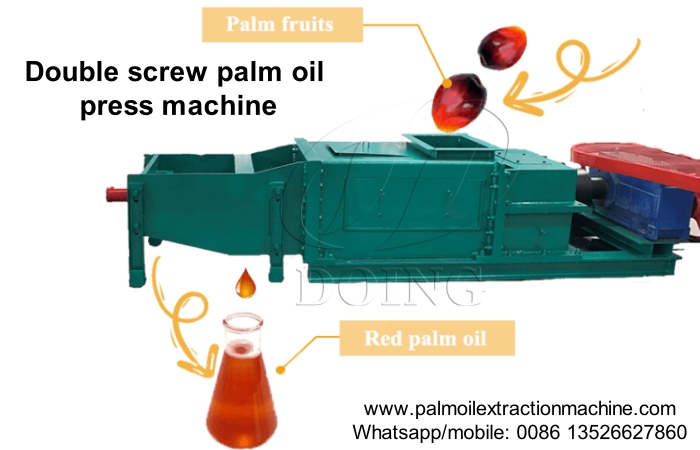

6. Pressing Equipment

Double screw palm oil press machine: An automatic hydraulic control system adjusts the gap between screws, and the palm fruits are squeezed and pushed forward in the pressing chamber, yielding crude palm oil. The machine is a core component of palm oil commercial production.

Double screw palm oil press machine

Double screw palm oil press machine

7. Clarification Equipment

-Sand trap tank: Separates crude palm oil from impurities via sedimentation.

-Vibrating screen: Removes fibers and large impurities from pressed oil using mesh screens.

-Plate filter: Removes fine impurities from the pressed oil through filter cloth.

8. Storage Equipment

Oil storage tank: It is used for the temporary storage of oil at various production stages and is typically equipped with a heating device to maintain the fluidity of the oil.

At this stage, you have obtained edible crude palm oil. If you want to improve the color and smell of the crude palm oil and further remove colloidal impurities in the crude palm oil, you can purchase the basic equipment of palm oil refining line.

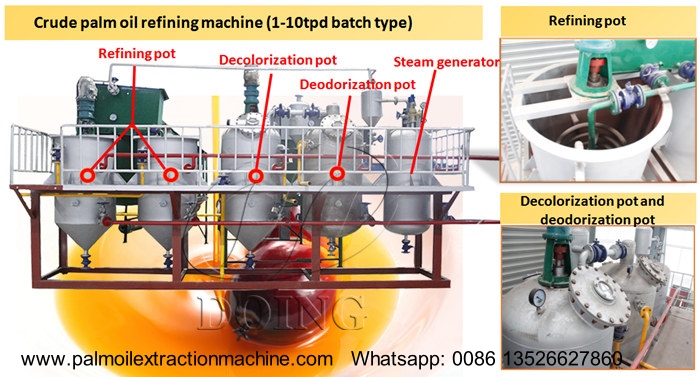

II. The Basic Equipment Needed for Palm Oil Refining Line

Crude palm oil refining equipment

Crude palm oil refining equipment

1. Degumming tank: The gums are precipitated by adding water or acid.

2. Deacidification tank: The FFA in the palm oil is neutralized by adding NaOH solution, separating soapstock from the oil.

3. Decolorization tank: Activated white clay is added to absorb impurities in the palm oil, such as pigments and residual soapstock.

4. Deodorization tank: Based on the principle of high-temperature vacuum distillation, heated steam is injected to evaporate the odorous components in the palm oil.

5. Thermal oil heater: Supplies thermal oil to support the refining process.

III. Supporting Equipment

1. Laboratory Equipment:

Quality control instruments: Test the quality of palm oil to ensure compliance with industrial standards before being sold.

2. Packaging Equipment

Filling and packaging machines: Once the palm oil is refined, it is packaged for sale, typically in bottles, drums, or bulk containers.

The palm oil filling and packaging machines

The palm oil filling and packaging machines

3. Waste Treatment Equipment

Effluent treatment plants (ETP): Palm oil mills produce wastewater that requires treatment including the addition of softeners and deoxidation processes, to minimize impact on environment and contribute to the sustainable development of commercial palm oil production.

The equipment mentioned above enables the smooth operation of your palm oil commercial production. If you are interested in palm oil production equipment, please feel free to contact us.

PREV:Nothing

PREV:Nothing

NEXT:Optimize your palm oil production line: fractionation process & machinery explained

NEXT:Optimize your palm oil production line: fractionation process & machinery explained

Leave A Message

If you wanna to get more details about What are the basic equipment needed for a palm oil commercial production? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

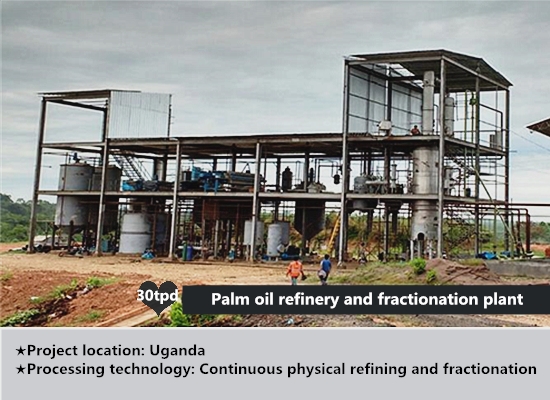

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-