Congratulations! In January 2024, the 3tph small scale palm oil mill plant project in Uganda was successfully installed and put into operation. This 3tph small scale palm oil mill plant was custom-designed by engineers from Henan Glory Company using advanced technology, tailored to the specific needs of the Ugandan client.

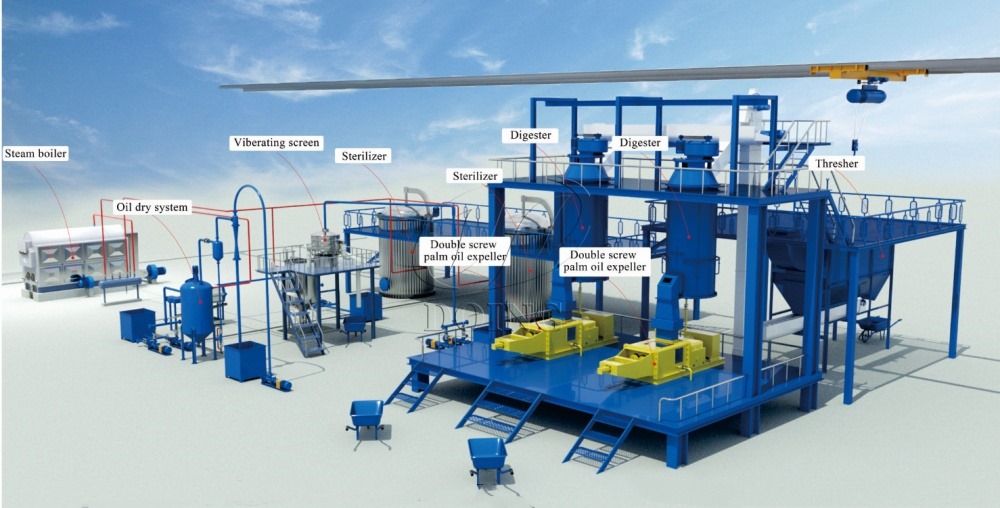

The core of this project is processing fresh palm fruit to obtain crude palm oil. The complete 3tph small scale palm oil mill plant includes key equipment such as palm fruit sterilizer, palm fruit thresher, palm fruit digester, palm oil presser and oil clarifiers. This equipment efficiently processes fresh palm fruit into crude palm oil, significantly improving the client's production efficiency and earning high praise from the client.

The complete 3tph small scale palm oil mill plant

The complete 3tph small scale palm oil mill plant

The Ugandan client was originally an edible oil intermediary and planned to establish his own small scale palm oil mill plant. On May 27, 2022, he contacted our company to inquire about palm oil production equipment. Our sales manager provided several solutions. After joint research by the client's project team and our engineers, he ultimately determined their comprehensive production line needs, including palm oil pressing and palm kernel oil pressing. Having thoroughly understood his requirements, we provided detailed information on key aspects such as equipment materials and oil yield through 3D videos, actual machine photos, and video conferences. Finally, the client placed an order on August 26, 2022.

While the client was preparing his plant, Henan Glory Company also began designing and manufacturing the customized palm oil production equipment. After approximately one year, we completed the manufacturing task on time and to a high standard. All equipment underwent rigorous testing before leaving the factory to ensure stable operation. On July 25, 2023, all equipment was packaged and successfully shipped to Uganda.

On-site packing pictures of equipment shipped to Uganda

On-site packing pictures of equipment shipped to Uganda

After the 3tph small scale palm oil mill plants arrived at the client's factory, we immediately dispatched professional engineers to the site for installation, commissioning, and troubleshooting, while also training the operators. The 3tph small scale palm oil mill plant was installed and entered the trial operation phase in January 2024. The successful operation of this main line laid the foundation for subsequent palm kernel processing.

On-site pictures of all equipment installed in Uganda

On-site pictures of all equipment installed in Uganda

Recommended Reading: This project also includes a 【5TPD Small Scale Palm Kernel Oil Processing Plant Project in Uganda】, utilizing the pressed palm kernels for processing, thus achieving full utilization of materials.

From the above introduction, you can gain a basic understanding of the 3tph small scale palm oil mill plant project in Uganda. As a professional edible oil equipment manufacturer, we have accumulated rich experience in project design, production, and installation. If you also want to build a palm oil mill plant or are interested in palm oil production equipment, please feel free to contact us! We will design your plant and recommend suitable equipment based on your budget and technical requirements.

Please answer the questions bellow before leaving the message. Our sales manager will contact you within 24 hours. And your contact information will be protected!