Optimize your palm oil production line: fractionation process & machinery explained

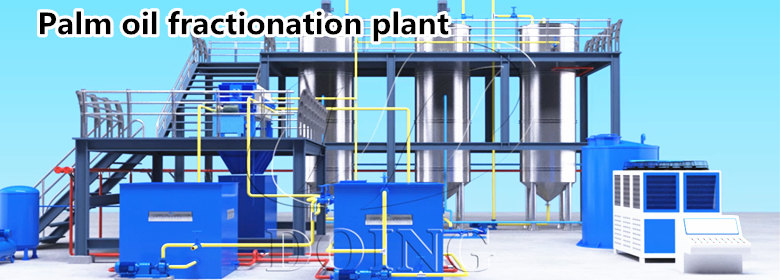

The natural characteristics of palm oil determine that it will form components with different melting points at different temperatures. The palm oil fractionation process uses this characteristic to separate palm oil into liquid palm oil and solid palm stearin by controlling the cooling and filtration process, thereby greatly expanding the application range of palm oil. By optimizing this link in the palm oil production line, customers can use it to improve product applicability, improve food quality and health, and expand applications in non-food industries. The following will introduce why it is necessary to optimize the palm oil production line as well as the palm oil fractionation process and machinery.

What is Palm Oil Fractionation Process?

Palm oil fractionation process achieves product diversification through physical separation. The core of the process lies in crystallization control, and parameters need to be adjusted in combination with production goals. Palm oil fractionation process optimize palm oil production line. Its advantages are mainly reflected in the following aspects: improving product diversity, improving oil performance, and increasing economic benefits, etc. This step is essential for producing high-quality cooking oil, margarine, shortening, and specialty fats. The palm oil fractionation process achieves efficient utilization of resources through physical separation, taking into account functionality, healthiness and economy, and is one of the key technologies in oil processing.

Palm Oil Fractionation Process & Machinery Explained

1. Palm Oil Fractionation Pretreatment Machinery

The heating tank heats the crude oil to 60~70℃ .

2. Palm Oil Fractionation Core Machinery

· Crystallization system

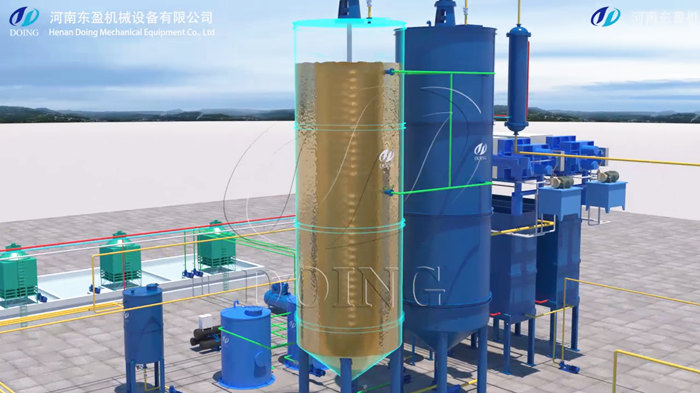

The crystallization tank is a closed container with stirring and cooling devices. The oil is pumped into the crystallization tank and slowly cooled to the initial crystallization temperature (usually 45-50°C) through a heat exchanger. Slow stirring (10-20 rpm) ensures uniform growth of crystals and avoids local overheating. During the crystallization process of palm oil fractionation, high melting point triglycerides (such as stearin) are formed into crystals by slow cooling.

Crystallization tanks section

Crystallization tanks section

· Water cooling circulation system

It is used to accurately control the cooling rate to ensure stable growth of crystals.

· Solid-liquid separation system

The plate and frame filter is a commonly used traditional method, suitable for small-scale production, with a filter cloth pore size of 5~10μm. The operating pressure is -0.08~-0.1 MPa, and the separation efficiency is >90%. Olein is the low melting point part, in liquid form, flowing out through the filter. Stearin is the high melting point part, and solid crystals remain on the filter cloth.

· Temperature control system

The refrigeration unit provides cooling medium (such as cold water, refrigerant) to control the crystallization temperature (usually 0~25℃). Plate or tube heat exchanger is used for oil temperature regulation.

The above is an overview of the palm oil fractionation process and palm oil fractionation machinery. The palm oil fractionation process optimizes palm oil production line and it is a complex technology that can fully realize the potential of this versatile vegetable oil. By selectively separating its components into specialized fractions, it can meet the various needs of the food industry while improving product quality and functionality. With the continuous development of palm oil fractionation process, the application prospects of palm oil in food and non-food fields will be further expanded.

PREV:What are the basic equipment needed for a palm oil commercial production?

PREV:What are the basic equipment needed for a palm oil commercial production?

NEXT:What must be avoided during the palm oil pressing process?

NEXT:What must be avoided during the palm oil pressing process?

Leave A Message

If you wanna to get more details about Optimize your palm oil production line: fractionation process & machinery explained . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

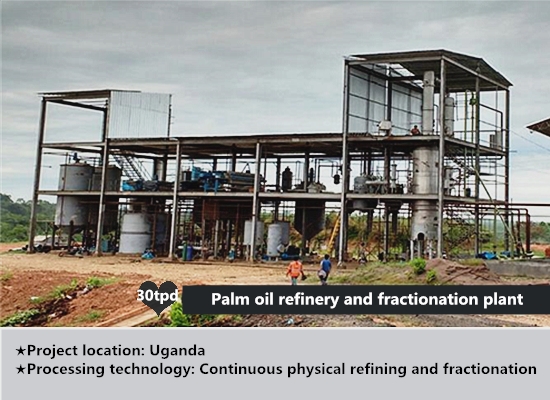

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-