Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

On January 9, 2020, one set of small scale palm kernel cracker and shell separator machine was successfully installed in Sierra Leone. From palm kernel cracker and shell separator machine production to the completion of installation and commissioning, this small scale palm kernel oil mill project has experienced a total of five months.

Small scale palm kernel cracker and shell separator machine project was successfully installed in Sierra Leone

Small scale palm kernel cracker and shell separator machine project was successfully installed in Sierra Leone

This palm kernel cracker and shell separator machine was ordered by one of customer from Sierra Leone, who has been engaged in palm kernel oil processing business for years. Before buying this palm kernel cracker and shell separator machine, he mainly bought the clean kernels to produce palm kernel oil, but it is rather costly, which lead to limited profit, and he also thought it was not cost-effective. In the meantime, he found that it is cheaper to buy palm nuts directly, but considering that palm nut is hard and difficult to deal with, he didn't find good solutions. Over the years, he has been trying to find one machine which can process palm nuts to kernels and shell quickly. After long time searching, finally he found the running video of the palm nut cracking and separating system manufactured by Henan Doing Group on YouTube. He got very interested and after then, he tried to contact with us and learn more information about this machine. The more he knew about our machine, the more he got interested in stepping into this business, finally he was won over by our machine quality and efficiency.

In order to further understand the performance and work situation of this palm kernel cracker and shell separator machine, this Sierra Leone customer came to China and visited our factory. After a few days of in-depth communication with our engineers, he found that this device is his ideal device. To let this machine can put into production early, he paid the deposit on the spot. The following is the specific progress of this project.

The whole palm kernel cracker and shell separator machine project can be divided into three stages, they are: production & delivery stage; Installation stage and Debugging stage:

Photos of production & delivery stage:

Palm kernel cracker and shell separator machine production and delivery photo

Palm kernel cracker and shell separator machine production and delivery photo

Photos of installation stage:

Our engineer was guiding the installation of palm kernel cracker and shell separator machine in Sierra Leone

Our engineer was guiding the installation of palm kernel cracker and shell separator machine in Sierra Leone

Photos of debugging stage:

Palm kernel cracker and shell separator machine has put into produciton in Sierra Leone

Palm kernel cracker and shell separator machine has put into produciton in Sierra Leone

Now, this palm kernel cracker and shell separator machine has put into production which can help Sierra Leone customer process about 3tons of palm nuts per hour. It greatly increased the efficiency of palm kernel processing. Our customer is very happy with the results. To show his gratitude to Henan Doing Machinery, our customer promised us that he would continue to choose to buy palm kernel oil machine from our company when he expanded production in the future.

Leave A Message

If you wanna to get more details about Palm kernel cracker and shell separator machine successfully installed in Sierra Leone . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

-

2tph Palm Oil Processing Equipment and Palm Kernel Oil Extraction Machine Project in Nigeria

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

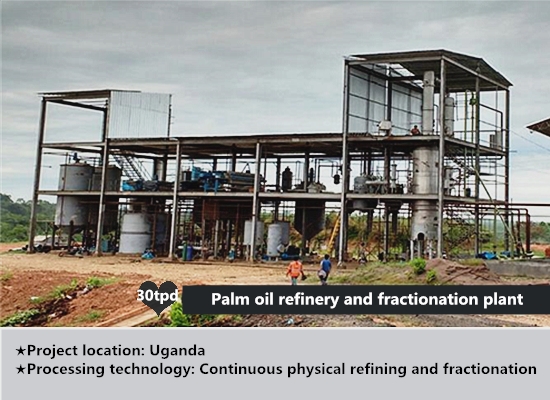

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

- What are the basic equipment needed for a palm oil commercial production?

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown