How to make clear organic palm kernel oil?

Clear organic palm kernel oil also called palm kernel oil is widely used in the food industry, palm kernel oil soft fat, hard fat can be used in cream, ice cream (especially fat), soap, can replace coconut oil and cocoa butter. Since palm kernel oil is so versatile and valuable, more and more customers want to know the production process and equipment of palm kernel oil.

Palm kernel oil extraction process

Palm kernel oil extraction process

Palm is mainly grown and planted in tropical areas such as Nigeria, Ghana, Malaysia, etc. Palm kernel is the core of palm fruit. Generally, the mixture of fiber and core obtained after palm fruit pressing is collected and stored in a centralized manner. Because the palm nuts has a hard shell, which is not conducive to the extraction of palm kernel oil. Before extracting palm kernel oil, the palm kernel must be peeled and separated first by using professional palm kernel cracking and separating system. Our palm kernel cracking and separating system can adjust the distance between the peeling machine tooth plate and the beater according to the size of the palm nuts. On the basis of the crushing of the shell, the integrity of the kernel is guaranteed, so that the subsequent cyclone separation equipment can ensure the efficient separation of the shell and the palm kernel. What's more, the shelling and separation rate of palm kernel cracker and separator can reach 97%.

Palm kernel cracking and separating machine

Palm kernel cracking and separating machine

Next, the obtained complete palm kernel will enter the palm kernel oil pressing production line for processing. Because the palm kernel is very hard, we usually need to use palm kernel crusher machine to crush palm kernel to small pieces to reduce the wear rate of the machine and improve the oil yield. And then, we need to use oilseeds roastor to adjust the moisture and temperature to achieve the best extraction index , so that the oil can be extracted as much as possible and the residual oil rate can be reduced. After that, the prepared palm kernel will be sent to palm kernel oil press machine to produce palm kernel oil. Our palm kernel oil press can guarantee a residual oil rate of 6-7%, saving time and effort after pressing once. The main parts are forged with 45-gauge steel, and the other large parts are cast iron and ductile iron. The forging process is different: forging, immersion, quenching, the purpose is to increase the hardness. There are some ordinary carbon steels palm kernel oil press machine on the market, but they have a short service life and are not durable. The palm kernel cake after pressing is thin and dry, which is no way to get the best pressing effect.

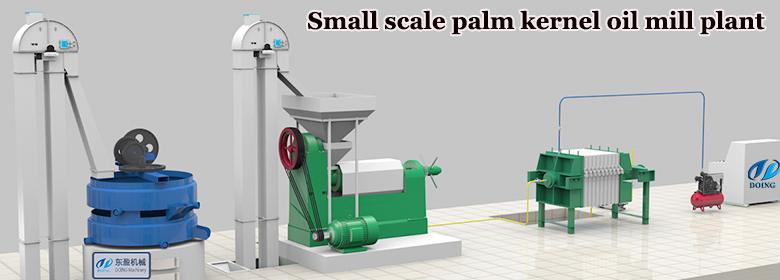

Small scale palm kernel oil processing machine

Small scale palm kernel oil processing machine

Finally, we need to use a filter to simply filter palm kernel oil to obtain clean palm kernel oil. If you want to store your palm kernel oil for a longer period of time. The crude oil needs to be refined.

Plate filter machine used to filter crude palm kernel oil

Plate filter machine used to filter crude palm kernel oil

As a professional manufacturer of oil and fat equipment research and development, production, installation and commissioning, Henan Glory Company can provide you with complete palm oil / palm kernel oil processing machine equipment list and quotations. If you want to know more about our equipment, welcome to consult us.

PREV:How long will it take to ship palm oil processing machine to Côte d'Ivoire?

PREV:How long will it take to ship palm oil processing machine to Côte d'Ivoire?

NEXT:What is the best palm oil processing equipment to buy for new investors with limited cost?

NEXT:What is the best palm oil processing equipment to buy for new investors with limited cost?

Leave A Message

If you wanna to get more details about How to make clear organic palm kernel oil? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

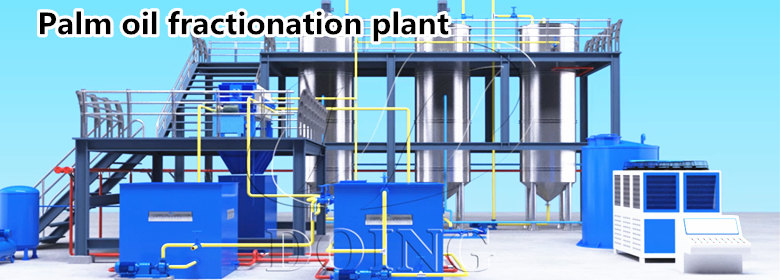

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

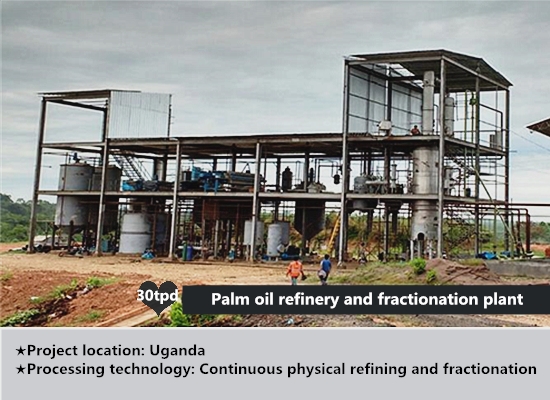

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-