How many kg of palm kernel cake (PKC) will 1 ton palm kernel nuts produce?

If you're involved in the palm kernel nut processing industry, you've likely grappled with this question: How many kg of palm kernel cake (PKC) will 1 ton palm kernel nuts produce? Understanding this crucial yield metric is essential for making informed decisions, optimizing production processes and maximizing profitability. This article will answer this question and many other related questions for you.

1. The Science Behind Palm Kernel Cake (PKC) Yield

Palm kernels contain a lot of oil, water and solids that form palm kernel cake. On average, palm kernels contain about 50-55% oil, 6-8% moisture, and 37-44% solids (which become PKC after palm kernel oil extraction). Therefore, under typical industrial conditions, 1 ton of palm kernel nuts can produce 370-440 kg of palm kernel cake (PKC). However, this is only a rough estimate. Palm kernel cake (PKC) yields vary depending on factors such as the palm kernel variety, growing conditions and processing technology used.

2. Palm Kernel Cake (PKC) Production Process

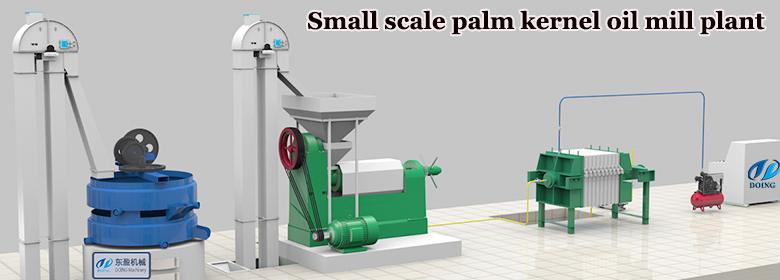

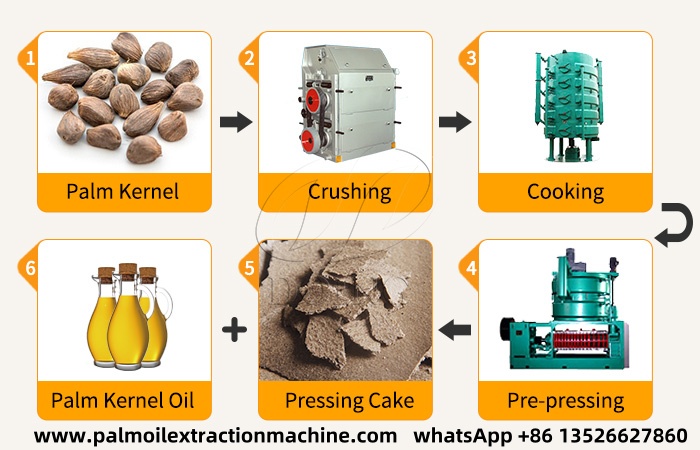

Palm kernel cake (PKC) production is a multi-step process. First, the palm kernel is cleaned to remove impurities. Then, the palm kernel is cracked to separate the kernel from the nut. Next, the palm kernel is cooked to adjust the internal moisture content, and then pressed to extract the palm kernel oil, leaving the remaining solid matter as palm kernel cake (PKC).

Palm kernel cake (PKC) production process

Palm kernel cake (PKC) production process

3. Factors Affecting Palm Kernel Cake (PKC) Production

(1) Palm kernel oil content: The higher the palm kernel oil content, the less residual solid matter (PKC) after oil extraction.

(2) Drying control: The moisture content of palm kernel needs to be reduced to 6%-8%. Too high moisture content will increase the weight of palm kernel cake (PKC) after pressing, but may cause mold risk.

(3) By-product diversion: Some factories use kernels and shells for biomass power generation, reducing palm kernel cake (PKC) production but improving overall energy efficiency.

(4) Processing loss: Palm kernel loss during transportation and storage (such as insect pests, moisture and mold) directly reduces the total amount of processable palm kernel and indirectly reduces palm kernel cake (PKC) production.

Palm kernel cake (PKC)

Palm kernel cake (PKC)

4. Applications of Palm Kernel Cake (PKC) Production

(1) Animal feed: Rich in fiber and protein.

(2) Organic fertilizer: Slow release nitrogen and micronutrients.

(3) Bioenergy: Used as a renewable fuel source.

In conclusion, if you want to maximize the yield of palm kernel cake (PKC), you need to adopt a high-quality palm kernel oil pressing process and ensure the quality of palm kernels, etc. In addition, this by-product plays a key role in sustainable agriculture and industry, and is an asset that can turn waste into resource-efficient assets. If you want to know more about palm kernel cake (PKC) production, please contact Henan Glory Company(with branch and overseas warehouse in Nigeria) today to learn more about our palm kernel processing solutions and how we can help you achieve your production goals.

PREV:How many options for palm oil processing machine?

PREV:How many options for palm oil processing machine?

NEXT:How to efficiently utilize by-products from palm oil production?

NEXT:How to efficiently utilize by-products from palm oil production?

Leave A Message

If you wanna to get more details about How many kg of palm kernel cake (PKC) will 1 ton palm kernel nuts produce? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

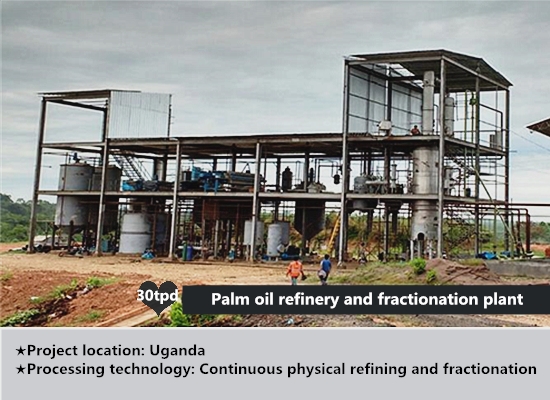

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-