What factors can Influence cracking and separation effect of palm kernel nut cracker and separator?

In the palm kernel oil production industry, efficient cracking and separation effect of palm kernels are crucial steps that significantly impact the overall productivity and quality of the final product. Then what factors can influence cracking and separation effect of palm kernel nut cracker and separator? As a professional manufacturer, Henan Glory will introduce it for you in details.

Factor 1: The quality, moisture content and size of palm kernel nuts will influence the palm kernel nuts cracking effect

The quality and size of the palm kernels themselves are major factors. Palm Kernel nuts that are overly dry or contain high moisture can be challenging to crack uniformly, leading to increased breakage rate of palm kernels and reduced yield of complete palm kernels.

Palm kernels and palm nuts photo

Palm kernels and palm nuts photo

So Henan Glory's palm kernel nut cracker and separator equipped a well-adjusted grading screen, which can separate different size of palm kernels, then let them through different cracker to make sure the completeness of palm kernels.

Factor 2: The design of palm kernel nut cracker will influence the palm kernel nuts cracking effect

Before palm kernel nuts enter the palm kernel crackers, we design a magnetic separator, which plays a vital role in removing any metallic contaminants from the palm kernel nuts. The presence of metal fragments can damage the cracker's blades, leading to inefficient cracking and potential machine downtime. So regular maintenance and inspection of the magnetic separators are essential to maintain their effectiveness and extend the lifespan of the cracker.

Magnetic separator of palm kernel nut cracker and separator

Magnetic separator of palm kernel nut cracker and separator

Besides, the design and functionality of the palm kernel nuts cracker itself are also critical. Factors such as the material of the cracking blades, their sharpness, and the speed of the cracking process all contribute to the efficiency of kernel cracking.

Factor 3: The running effect of the wind separation column and cyclone system will influence the palm kernels and shells separating effect

Once cracked, the wind separation column and cyclone system play a pivotal role in separating the kernels from the shells. The airflow in these units must be precisely controlled to ensure that the lighter shells are separated from the heavier kernels effectively. Our wind separation column is visual, which makes it easy to see the separation effect clearly and ensure the normal operation of the machine. The cyclone is connected to an external fan to make the separated shells form a downward force, fall and be collected to ensure the cleanliness of the workshop.

The wind separation column and cyclone system

The wind separation column and cyclone system

Although there are many factors influence the cracking and separation effect of palm kernel nuts, Henan Glory company's palm kernel nuts cracker and separator system with reasonable design can make sure that you have a best cracking and separation effect. If you want to learn more about it, welcome to contact us!

Leave A Message

If you wanna to get more details about What factors can Influence cracking and separation effect of palm kernel nut cracker and separator? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

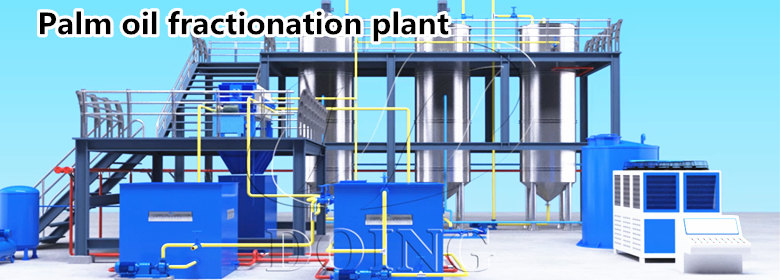

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

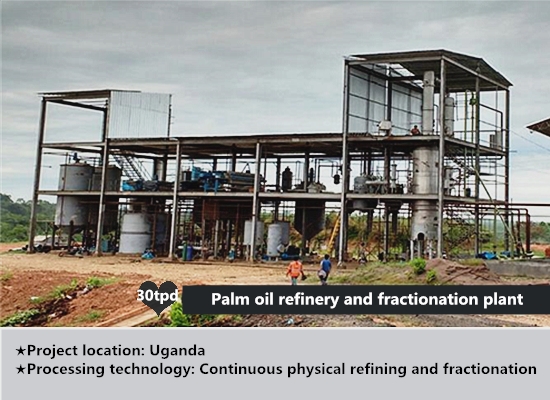

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-