What are the differences of different types of sterilizers in palm oil pressing mill?

The equipment involved in palm oil pressing mill mainly contains sterilizer, thresher, digester and palm oil expeller, vibrating screen, plate filter, etc. Besides the palm oil presser, the sterilizer is the second most important equipment. There are so many different types of sterilizers in the market, so here Henan Glory introduces their differences to help you choose the right one you prefer.【Recommended reading: Why is it necessary to sterilize the palm fruit bunches first and then separate the palm fruit in the large-scale palm oil mill production process?】

In large scale palm oil pressing mill, there are mainly three types of applicable sterilizers: vertical sterilizer, horizontal sterilizer and inclined sterilizer. Among them, the most frequently used are vertical sterilizer and horizontal sterilizer. So here we will mainly introduce the differences of these two kinds of sterilizers.

| Sterilizer types | Vertical sterilizer | Horizontal sterilizer |

| Footprint difference | Covers a small area | Covers a large area |

|

Automatic degree difference |

High degree of automation, with automatic opening door, and it requires less labor; | Composed of multiple trolleys, and the degree of automation is relatively low and requires more labor; |

| Investment cost difference | Higher price | Lower price |

Vertical sterilizer and horizontal sterilizer

Vertical sterilizer and horizontal sterilizer

In small scale palm oil pressing mill with processing capacity less than 10tph, there are also three types of applicable sterilizers. And they also have different applications and features.

| Sterilizer types | Heating method | Sterilization time |

| Boiled sterilizer | Without a steam boiler, directly burns hot water to produce steam for heating. | 90-120 minutes |

| Steam-boiler sterilizer | The steam boiler (with automatic opening door) will provide steam for heating. | 60-90 minutes |

| Vertical-steam sterilizer | Use a boiler and heat through the outer heating coil, which is more efficient. No palm fruit cages is needed. |

60-90 minutes |

If you have any query about these sterilizers and palm oil mill plant, please contact Henan Glory Oils & Fats Engineering Co., Ltd. We have the professional engineers team with rich experience to customize the most suitable palm oil milling machine and processing solutions!

Leave A Message

If you wanna to get more details about What are the differences of different types of sterilizers in palm oil pressing mill? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

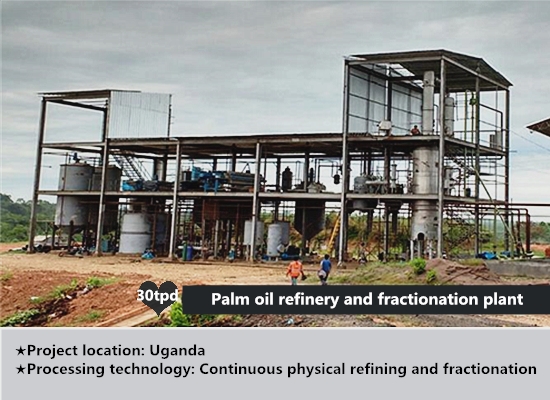

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-