What is the process of making palm oil?

Oil palm is a kind of important tropic oil seed plant, the oil rate in oil palm is very high: generally 46~50% in the fresh pulp, 50~55% in palm kernel. As for the process of making palm oil from palm fruit, it is subtle differences according to customer’s different equipment.Here, Henan Glory Company will take the standard palm oil pressing production line as an example, introducing the standard process of making palm oil.

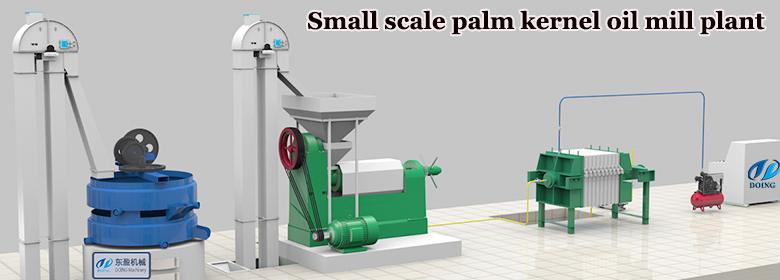

Small scale palm oil processing machine

Small scale palm oil processing machine

Step 1: Raw material reception

As the saying goes, “before the soldiers and horses move, the food and grass go first”. The raw material reception station is to weigh the fresh palm fruit bunches, so as to ensure the quantity of fresh palm fruit bunches is enough for the palm oil pressing production line. The fresh palm fruit bunches are poured on the loading ramp to prepare for the next sterilization.

Step 2: Sterilizing

In sterilization station, palm fruit bunches are airtight sterilized in sterilizer, by injecting direct steam to heat. Sterilizing aims at destroying enzymes in the flesh to prevent the free fatty acid content in the oil from rising. On the other hand, the high temperature will make the fruit soften, it is easy for threshing and being prepared for the following-up process.

Palm fruit sterilizer

Palm fruit sterilizer

Step 3: Threshing

After sterilizing, the prepared palm fruit bunches will be sent to the thresher. The drum type thresher can easily separate the fruit and the bunches during rotating process. The separated palm fruit is transported by screw conveyors and bucket elevators to the digesting & pressing station for the next stage of the operation.

Palm fruit thresher machine

Palm fruit thresher machine

Step 4: Digesting & pressing

Next, the palm fruit will be sent to the digesting & pressing station. In digesting process, the palm pulp and nut will be separated, and the palm fruit will be crushed, even be destroyed its tissue.

And by pressing, it can extract the oil from the palm pulp. After pressing, we can obtain crude palm oil containing impurities and water, and a mixture of fiber and palm nuts. The mixture of fiber and palm nut can be sold or processed to press palm kernel oil.

Palm fruit digester machine and presser

Palm fruit digester machine and presser

Step 5: Clarifying & drying

Finally, the crude palm oil need clarifying and drying because it contains a lot of impurities and water. It usually use vibrating screen, clarification tank and plate filter to remove the impurities from the crude palm oil, and use oil drying system to dry the crude palm oil.

Palm oil clarification machine

Palm oil clarification machine

Till this step, the whole standard process of making palm oil is finished, and we can get red crude palm oil. You can directly sell crude palm oil or further refined to obtain RBD palm oil.

The standard process of making palm oil is a little complicated. If your daily processing capacity is less than 1 ton per hour, our engineer can also design the simple process of making palm oil for you, and some steps can replaced by workers or small scale machines. Tell us your requirement, we will give you the free quotation. PREV:What equipment is needed for palm kernel oil production?

PREV:What equipment is needed for palm kernel oil production?

NEXT:What should be paid attention to when selecting a palm oil plant site?

NEXT:What should be paid attention to when selecting a palm oil plant site?

Leave A Message

If you wanna to get more details about What is the process of making palm oil? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

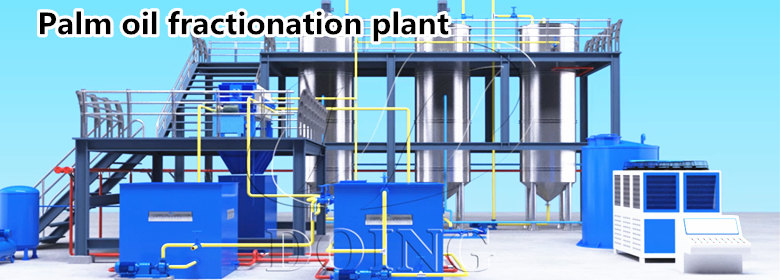

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

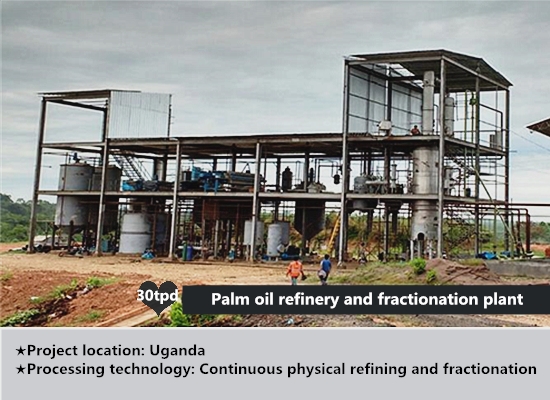

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-