What are the eight steps involved in crude palm oil extraction?

The complete specific eight detailed steps of crude palm oil extraction include raw material reception, sterilization, threshing, digesting, pressing, filtering process and vacuum dryer system and storage. Here are the specific processes of crude palm oil extraction.

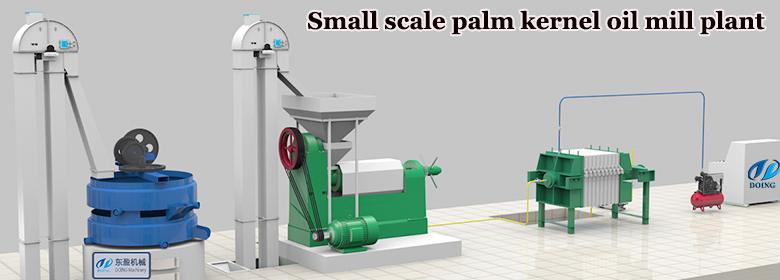

Palm oil extraction machine

Palm oil extraction machine

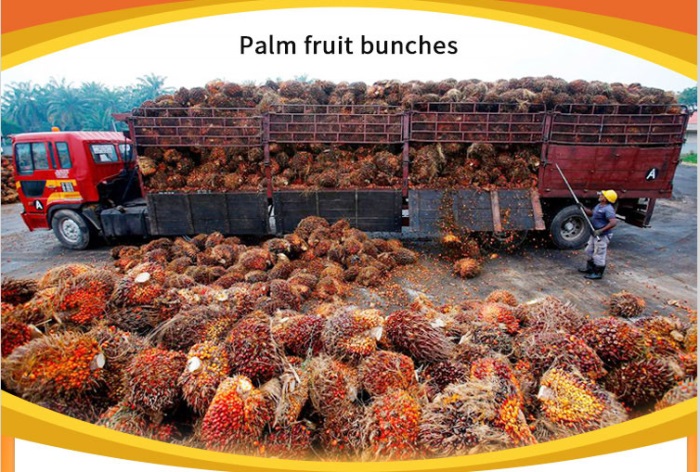

The first is raw material reception in crude palm oil extraction. Fresh palm bunches collected from plantations need to be treated within 48 hours to prevent FFA from increasing and affecting the quality of the oil later on. They are transported by truck or other means to the factory, weighed and put into the unloading table for other processes.

Step two is sterilization section in crude palm oil extraction. The purpose of this step is to soften and sterilize the fruit so that it is easy to fall off and press.

Palm fruit sterilizer

Palm fruit sterilizer

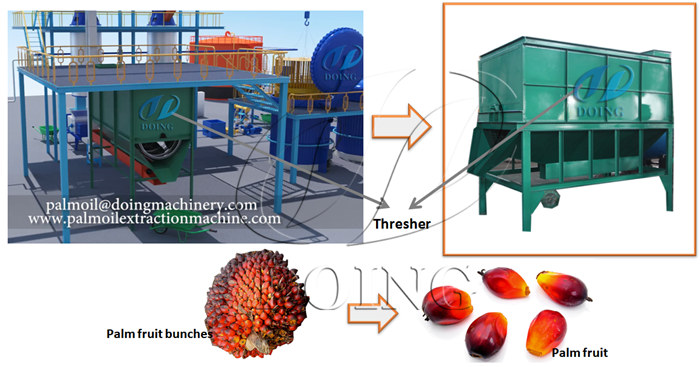

Step three is threshing section in crude palm oil extraction. Use a thresher machine to separate the fruit clusters that have been sterilized. The goal is to separate palm fruit from FFB. The empty bunches are collected for fuel or fertilizer, and the fruit moves on to the next stage.

Palm fruit thresher

Palm fruit thresher

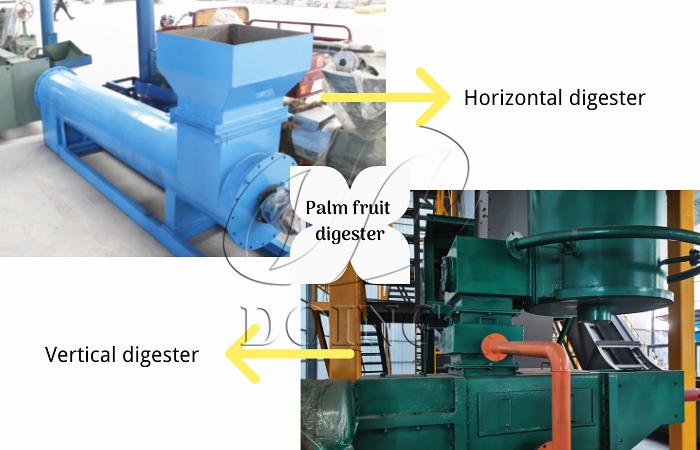

The step four is digesting in crude palm oil extraction. The destruction of the fiber structure facilitates subsequent pressing and helps to improve the final oil yield.

Palm fruit digester

Palm fruit digester

The fifth step is the pressing section in crude palm oil extraction. This is an important step. The oil press is used to press the palm fruit. The fruit and nut are separated from the front part of the oil press and extruded to get crude palm oil and palm nut. The oil press produced by Henan Glory Company has high oil yield and can maintain continuous production.

Screw palm oil press machine

Screw palm oil press machine

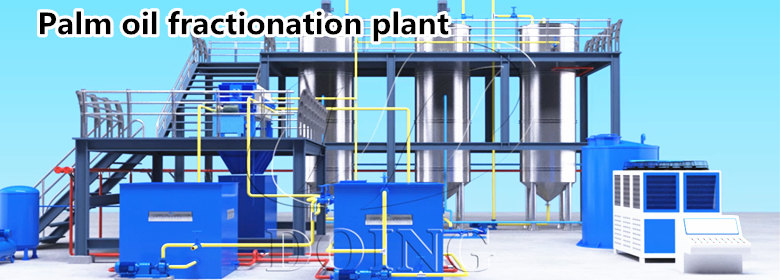

The sixth and seventh steps are filtering process and vacuum dryer system in crude palm oil extraction. CPO is subjected to a series of filtering processes such as vibrating screen, oil clarification tank and plate filter, layer by layer filtration to ensure the quality of oil. If the water in the oil is not removed, it is difficult to keep it for a long time, so a vacuum drying system is needed. The water in the clean oil under the vacuum condition is stirred to evaporate, and can be directly put into the crude oil tank after drying.

Palm oil clarification machine

Palm oil clarification machine

The final step is the storage and crude palm oil transportation in crude palm oil extraction. The crude oil is transported by truck or other means and stored.

Palm oil storage tank

Palm oil storage tank

These are the eight steps in crude palm oil extraction. Henan Glory Company has been engaged in this industry for more than ten years and can provide all machines required for these steps in crude palm oil extraction. If you are interested, please contact us.

PREV:How does the palm oil processing plant produce palm oil?

PREV:How does the palm oil processing plant produce palm oil?

NEXT:What key points are there when making palm oil mill factory design and layout?

NEXT:What key points are there when making palm oil mill factory design and layout?

Leave A Message

If you wanna to get more details about What are the eight steps involved in crude palm oil extraction? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

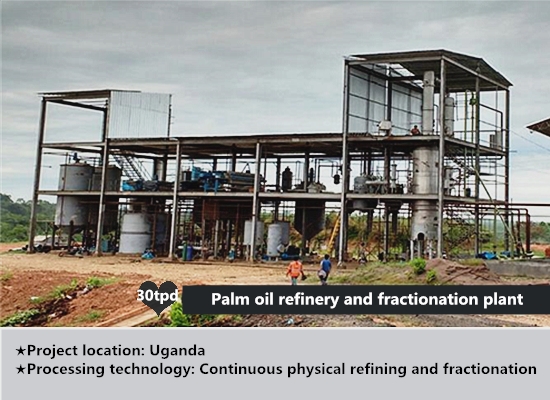

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-