How does the palm oil processing plant produce palm oil?

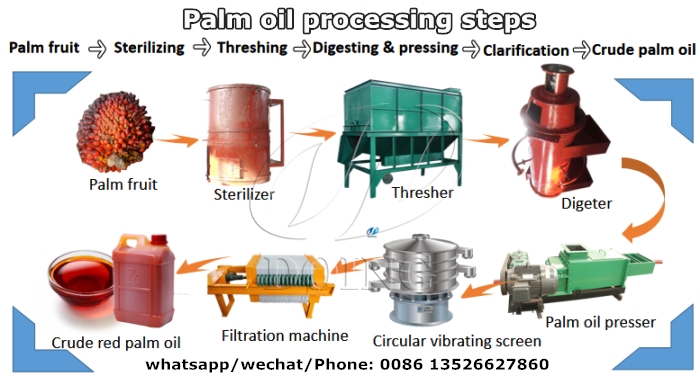

Palm oil is the most demanded edible oil in the world, but the palm oil processing process varies around the world due to raw materials, budget and requirements. Here, we will take medium or large palm oil processing plant as an example, the complete palm oil production process generally include sterilizing, threshing, digesting, pressing and filtering.

Palm oil processing process

Palm oil processing process

First of all, put the fresh fruit bunches into the fruit cage, and put the fruit cage into the sterilization tank for sterilization with a row hanger. However, we recommend using a steam sterilizer when the palm oil extraction plant has a capacity greater than 5 tph. The conveyor belt transports the fresh fruit bunches directly to the sterilizer, so fruit cages are not required. This method is more automated. The role of palm fruit sterilization is to increase the humidity of the fruit, destroy the activity of lipolytic enzymes, and slow down rancidity, thereby preventing the increase of free fatty acid (FFA) content.

Palm fruit sterilizer

Palm fruit sterilizer

Secondly, the sterilized palm fruit bunches are threshed in a drum thresher, and the fruit is dropped by physical collision. The obtained palm fruit is conveyed to the digesting tank by screw conveyor and bucket elevator. Digesting fruit is for better oil extraction. Part of the oil produced during the crushing process will be temporarily transported and stored in temporary storage tanks. The digested palm fruit is then pressed in a palm oil press. After processing, you can get crude palm oil and a blend of palm fibers and nuts.

The final step is to filter the crude palm oil in a palm oil processing plant. The vibrating screen filters large fibers, the clarifier filters heavy impurities and sediment, and the plate filter filters fine fibers and absorbs water. The vacuum drying system realizes the separation of palm oil and water, and draining the water is beneficial to crude palm oil storage. In addition, the vibrating screen is double-layered. The clarifier has a built-in heating coil, which can increase the fluidity of the oil due to the low melting point of crude palm oil. In order to better storage crude palm oil, the vacuum drying system is carried out under vacuum and high temperature.

Palm oil filtering section

Palm oil filtering section

The greater the processing capacity, the more equipment is needed to ensure production efficiency and automation in palm oil processing plant. The processing process of palm oil is not complicated, and each piece of equipment plays an important role. If you have any needs for palm oil production, please contact us.

Leave A Message

If you wanna to get more details about How does the palm oil processing plant produce palm oil? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

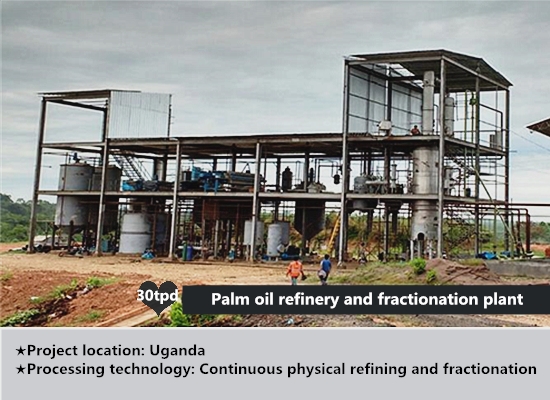

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-