What are the precautions of ensuring the performance of palm kernel cracking and shell separating system?

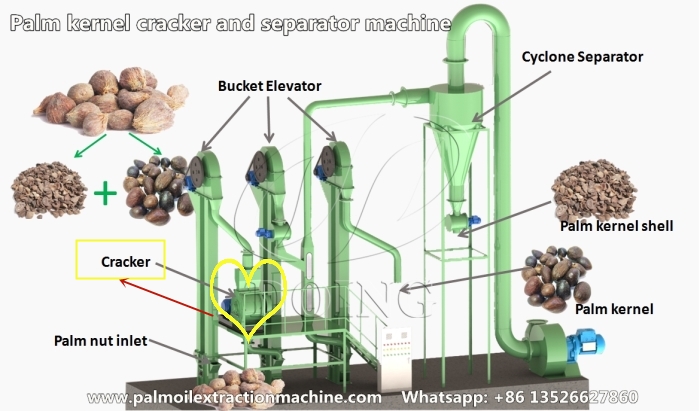

Palm kernel cracking and shell separating system is a crucial component of the palm kernel oil production line. This system is designed to separate the palm nut shell from the kernel quickly and efficiently, achieving high cracking and separation rates. However, several factors can affect the performance of palm kernel cracking and shell separating system, and it is essential to take precautions to ensure optimal performance.

Palm kernel cracking and shell separating system

Palm kernel cracking and shell separating system

1. Using high-quality palm nuts for complete separation and efficiency

It is also crucial to use high-quality palm nuts when using palm kernel cracking and shell separating system. Using low-quality palm nuts can result in incomplete separation and reduce the performance of the system.

2. Removing fiber from palm nuts for effective shell peeling

One of the critical factors that can affect the performance of palm kernel cracking and shell separating system is the presence of fiber on the palm nuts. If there is fiber on the palm nuts, it can clog the cracker and affect the effectiveness of shell peeling. Therefore, it is crucial to remove the fiber from the palm nuts before using the system.

3. Importance of keeping palm nuts dry for optimal cracking and separation

Another factor that can affect the performance of palm kernel cracking and shell separating system is the moisture content of the palm nuts. If the palm nuts are too moist, it can hinder the cracking and separation process. Therefore, it is essential to keep the palm nuts dry before using the system.

4. Adjusting cracker for palm nut size to maximize cracking rate

Adjusting the cracker according to the size of the palm nuts is also crucial to achieve the best cracking rate. If the cracker is not adjusted for the size of the palm nuts, it can reduce the cracking rate and result in incomplete palm kernel separation.

5. Monitoring wind separation column for efficient shell separation

Monitoring the wind separation column is also essential to ensure efficient shell separation. If there are many shells in the falling palm kernel, it is necessary to adjust the wind speed of the fan promptly to prevent clogging and ensure optimal separation.

6. Proper installation and regular maintenance of critical equipment parts for optimal performance

Regular maintenance of critical equipment parts and proper installation and maintenance are two crucial factors that affect the performance of palm kernel cracking and shell separating system. Regularly checking the equipment’s critical parts is essential to ensure optimal performance, as any malfunctioning parts can affect the system's efficiency and result in incomplete palm kernel separation. Additionally, proper installation and maintenance of the system are necessary to prevent clogging and ensure optimal performance. Regular maintenance and cleaning of the system can help prevent clogging and ensure optimal performance.

7. Importance of trained personnel for safe and efficient operation

Furthermore, it is essential to ensure that the system is operated by trained personnel who understand how to use the system correctly. Proper training can help prevent accidents and ensure that palm kernel cracking and shell separating system is used efficiently.

In conclusion, the palm kernel cracking and shell separating system is an essential component of the palm kernel oil production line. To ensure optimal performance, it is crucial to take precautions such as removing fiber from the palm nuts, keeping the palm nuts dry, adjusting the cracker according to the size of the palm nuts, monitoring the wind separation column, and regularly checking the equipment’s critical parts and so on. If you want to get more information, Henan Glory Company is here for you.

PREV:How to start palm kernel oil business in Nigeria?

PREV:How to start palm kernel oil business in Nigeria?

NEXT:How does the palm oil processing plant produce palm oil?

NEXT:How does the palm oil processing plant produce palm oil?

Leave A Message

If you wanna to get more details about What are the precautions of ensuring the performance of palm kernel cracking and shell separating system? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

- What are the necessary machines for efficient palm oil production of palm oil?

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

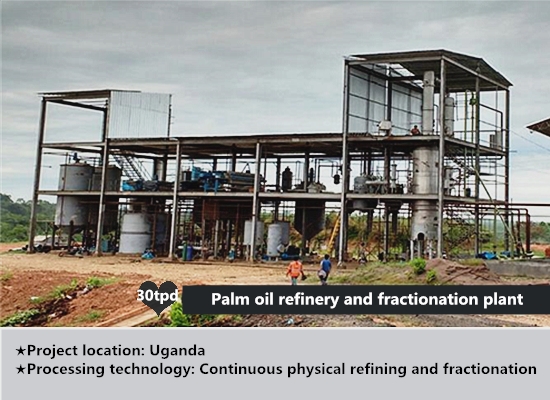

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-