What are the steps to produce palm oil?

Palm oil production process is a meticulous process that involves several stages, from the cultivation of palm trees to the final extraction and refining of the palm oil. This article outlines the key steps to produce palm oil, which mainly include planting and cultivation of palm trees, harvesting, transportation, sterilization, threshing, digesting and pressing, clarification, refining, quality control and packaging. Next I will introduce you one by one.

Step1、Planting and Cultivation:

The palm oil production process begins with planting high-quality palm tree seeds or seedlings in well-prepared soil. These palm trees require warm climates and ample rainfall for optimal growth. Once planted, the trees are regularly watered, weeded, and fertilized to ensure healthy growth.

Step2、Harvesting Palm Fruits:

After reaching maturity—typically between four and five years—palm trees start bearing fruits. These fruits, called palm fruits. Skilled workers carefully cut the bunches using machetes or specialized tools to avoid damaging the palm fruits.

The picture of lots of palm fruit bunches

The picture of lots of palm fruit bunches

Step3、Transportation:

Harvested palm fruits need to be transported from the plantations to the processing factory as quickly as possible to maintain their freshness. Long delays can lead to fermentation, affecting oil quality and yield.

Step4、Sterilization:

Upon arrival at the factory, the palm fruits undergo a sterilization process to eliminate any bacteria or fungi. Steam into the sterilizer and steam the palm fruits at high temperature for about 60 min, to destroy the enzymes in the palm fruits and avoid the increase of FFA content in the palm oil. This step ensures that the oil will be safe for consumption and extends its shelf life.

Step5、Threshing:

Then the sterilized fruit bunches are fed into a palm fruits thresher. Palm fruits thresher can separates palm fruits from palm fruit bunches. This results in a mixture of palm fruits and empty fruit bunches. Empty palm fruit bunches are discharged from the other side of the thresher, and then the EFB is transported to the yard, or to palm plantation as fertilizer or slipcover.

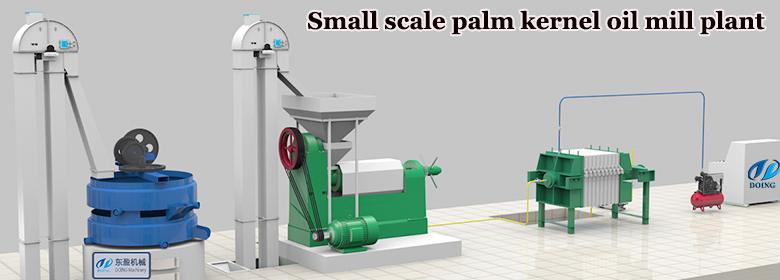

Three types of palm oil production machine with different processing capacities

Three types of palm oil production machine with different processing capacities

Step6、Digesting and Pressing:

Digesting is for pressing palm fruits, it can be make palm fruits be pressed oil out easily. The separated palm fruits are then processed for oil pressing. The fruits are initially pressed to produce the crude palm oil (CPO). This process separates the oil from the solid components, such as the palm kernel and fiber. Early pressing methods were manual, but modern factories use automated screw presses or expellers to increase efficiency and yield. The screw palm oil pressing machine provided by Henan Glory Company with high oil rate and low loss.

Single screw palm oil press and double screw palm oil press

Single screw palm oil press and double screw palm oil press

Step7、Clarification:

The produced crude palm oil contains impurities and non-oil components. Therefore, the extracted crude palm oil needs to be clarified to remove impurities. This may involve settling tanks where the oil is left to stand so that heavier particles sink to the bottom, followed by filtration or centrifuge processes.

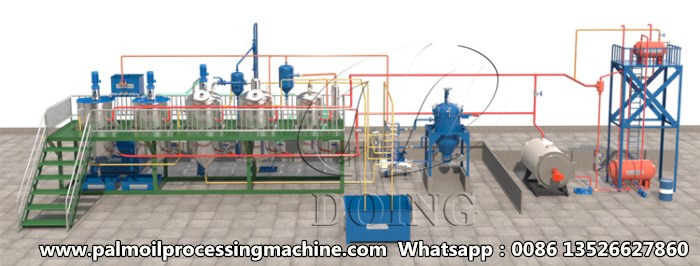

Step8、Refining:

Crude palm oil is refined to improve taste, color, and stability. Refining involves degumming, deacidification, decolorization, and deodorization processes. Degumming inhibits free fatty acids thereby increasing storage time, decolorizing removes pigments, and deodorizing eliminates bad odors.

Small scale palm oil refining machine

Small scale palm oil refining machine

Step9、Quality Control and Packaging:

Finally, the refined palm oil undergoes rigorous quality control tests to ensure it meets specified standards for taste, smell, color, and nutritional content. After approval, the oil is packaged into various containers for distribution to consumers or industrial clients.

The above are the steps to produce palm oil. In conclusion, the palm oil production process is intricate and demands precision at every step, from the initial care of palm trees to the final stages of packaging the refined product. Each stage plays a crucial role in determining the quality and yield of the oil. Henan Glory Company is a manufacturer specializing in the production and processing of palm oil production machine with a history of more than ten years. In addition, we can also customize palm oil production solutions for you based on your actual situation. If you need palm oil production machine, please feel free to consult us.

PREV:Palm oil and palm kernel oil production machines have been successfully sent to Uganda

PREV:Palm oil and palm kernel oil production machines have been successfully sent to Uganda

NEXT:What unit operations are involved in palm oil production?

NEXT:What unit operations are involved in palm oil production?

Leave A Message

If you wanna to get more details about What are the steps to produce palm oil? . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- What are the basic equipment needed for a palm oil commercial production?

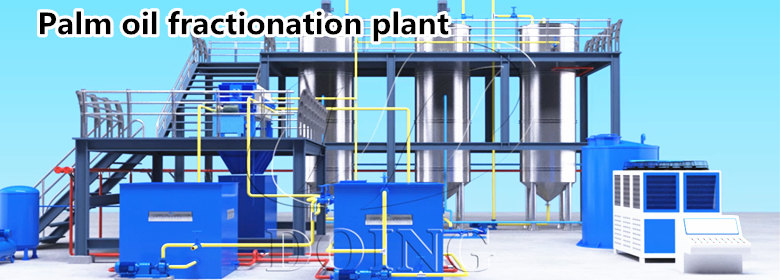

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

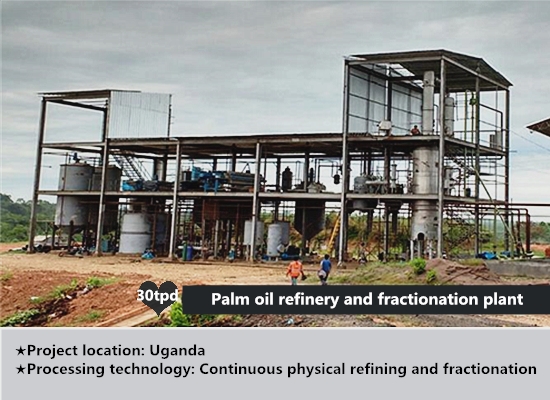

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-