The Production and Utilization of High Acid Crude Palm Oil

There are two main situations for the production of High Acid Crude Palm Oil. First, the palm fruit bundles are not processed in time after picking, resulting in an increase in free fatty acids; second, they are produced during the production of palm oil and is a by-product of the palm oil factory. This by-product is a potential source for biofuel applications with high economic advantages, which can be used as feedstock for biodiesel plants or as fuel for diesel engines for power generation.

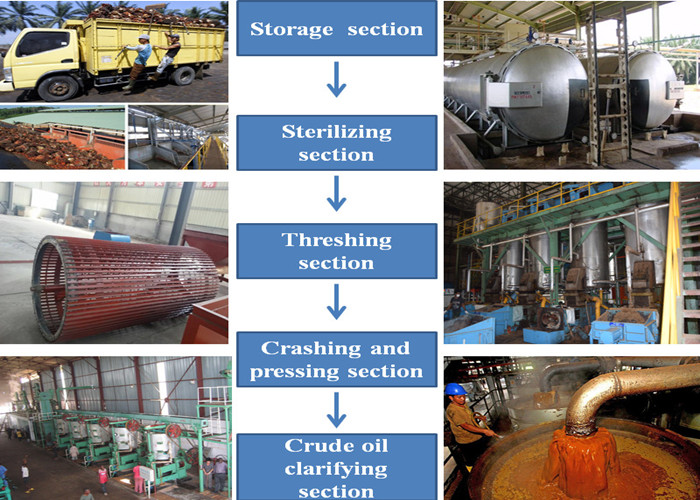

High Acid Crude Palm Oil including High fatty acid crude palm oil (HFCPO) and palm sludge oil (PSO) are by-products of palm oil mills. On the one hand, HFCPO is a by-product of non-food-grade oils made from loose fruit and overripe fresh fruit bunches. Oil palm fruit contains more lipolytic enzymes, so the harvested fruit must be processed or sterilized in time. Crude palm oil is easy to hydrolyze by itself to generate more free fatty acids, and the acid value increases rapidly. The content level of free fatty acids in palm oil actually depends on three factors: the degree of immaturity of the fruit (over-ripe fruit is easily damaged); the degree of ear pretreatment (fermentation); The delay time between transformations. Furthermore, PSO is a by-product of the sterilization process, residual oil in wastewater and oil in press cake or decanter sludge. On the other hand, High Acid Crude Palm Oil (HACPO or ACPO), another biodiesel feedstock with 8~15% free fatty acids, can also be used to produce biodiesel that complies with international biodiesel standards such as EN 14214 and ASTM D6751. Perchloric acid shows high catalytic activity for the conversion of FFAs to FAMEs and is also useful in the treatment of various acidic oils and fats.

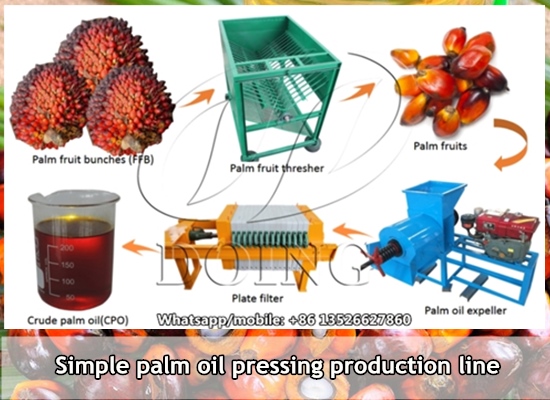

Palm oil production process

Palm oil production process

The price of HFCPO and PSO is much lower than the official quotation of crude palm oil (CPO). Both of these by-products are non-edible oils and cannot be eaten. However, This by-product has low price and environment-friendly so that can be a potential source for biofuel applications with high economic advantages.The esterification of the fatty acids contained in the acid oil can be replaced by a direct extraction method, namely, yielding a mixture of triglycerides and methyl esters, which can be readily esterified with current state-of-the-art biodiesel production technologies that require the use of low-acidity oils as feedstock exchanged for finished biodiesel production.The resulting product has a very low acidity mixture of methyl esters and triglycerides to extract the low acidity oil fraction from the acid oil without chemical reaction. By doing this, pure vegetable oil (SVO) is obtained, which can be used as feedstock for biodiesel plants or as fuel for diesel engines for power generation.

According to a test done in Indonesia,, the acid fraction separated from the oily fraction through the extraction process can be converted into FAME (Fatty Acid Methyl Esters). FAME is used to blend with regular diesel to achieve "Green Diesel" with huge economic profit. what is more, the generated "Green Power Production" and "Green Diesel" can be used for palm oil mills and self-owned electricity in local and international markets.

The above is a brief introduction of what High Acid Crude Palm Oil is and what the utilization of it is . In a word, this by-product is a potential source for biofuel applications with high economic advantages and can produce low acidity oil (raw material for biodiesel), vegetable oil (for power generation), and FAME (i.e. biodiesel). If you are interested in producing palm oil or build a palm oil mill, feel free to contact Henan Glory Company which are a professional oil equipment manufacturer.

PREV:How to start palm kernel oil business in Nigeria?

PREV:How to start palm kernel oil business in Nigeria?

NEXT:How much is the cost of 1tpd crude palm oil refining machine?

NEXT:How much is the cost of 1tpd crude palm oil refining machine?

Leave A Message

If you wanna to get more details about The Production and Utilization of High Acid Crude Palm Oil . you can send E-mail to palmoil@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

-

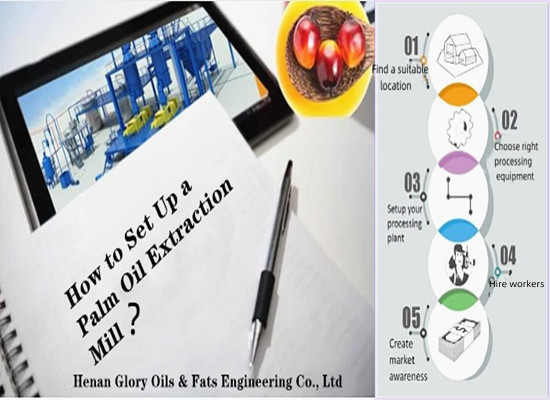

What does it take to start up a palm oil processing business?

-

-

-

-

How much is the cost of 1tpd crude palm oil refining machine?

-

How much does it cost to set up palm oil making machine for a small business?

-

What equipment is needed for small scale palm kernel oil refining plant?

-

What factors to consider when setting up a palm oil mill plant in Ghana?

-

What are the palm oil processing machines and their prices in Nigeria?

-

-

-

5tph palm oil processing machines project successfully installed in Liberia

-

1tph palm oil pressing plants project successfully installed in Lagos, Nigeria

-

-

-

-

-

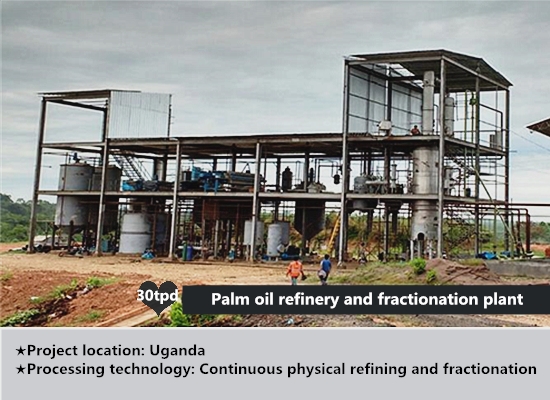

30tpd palm oil refinery and fractionation plant project in Uganda

-

Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

-

- What are the basic equipment needed for a palm oil commercial production?

- Optimize your palm oil production line: fractionation process & machinery explained

- What must be avoided during the palm oil pressing process?

- Step-by-step guide to operating a palm oil extraction machine safely

- How to improve the oil yield of the palm oil pressing process

- FAQs on palm oil fractionation process: key equipment and cost breakdown